Fungicides have become an integral part of the integrated pest management (IPM) for cereal production in Ontario over the past decade. This is due to several factors including: higher grain prices, better genetics, better fungicides, and breakdown of genetic disease resistance. Fungicide application for disease control should be based on scouting and presence of disease whenever possible. However, in the case of rust on oat or fusarium in wheat, fungicides must be applied as a preventative part of an IPM strategy if it is known that the likelihood of disease is high. Further information on disease identification and control can be found in Chapter 14, Diseases of Field Crops, and in OMAFRA Publication 812, Field Crop Protection Guide. Thresholds for disease control vary, depending on which disease is present, the stage of growth, crop condition and weather patterns. In general, it is important to scout the top two leaves of the cereal crop, at any stage of growth. If disease is moving onto one or both of these leaves, determine if the control threshold has been reached and if control is warranted.

Fungicide timing has moved to a new naming convention:

- early timings (Growth stage (GS) 30-31) are referred to as T1

- flag leaf timings (GS 37-39) are referred to as T2,

- fusarium timing (GS 58-61) are referred to as T3

In general terms, the later fungicides are applied to cereal crops, the higher the yield response, up until T3. Protecting the upper leaves of the cereal crop during grain fill has the greatest impact on yield. However, the yield difference between application at T2 and T3 is small. Earlier fungicide applications have less yield impact, as is shown in Table 4-12, Fungicide timing response. Economic yield response under Ontario growing conditions is marginal with 2 fungicide applications and rare with 3 fungicide applications. Where producers chose to apply more than one fungicide, use of different or multiple modes of action is essential to delay the development of disease resistance.

Table 4-12. Fungicide timing response

| Application Timing | Delta Yield |

| T1 | 0.11 t/ha (1.6 bu/acre) |

| T2 | 0.46 t/ha (6.9 bu/acre) |

| T3 | 0.54 t/ha (8.0 bu/acre) |

| T1 + T2 | 0.54 t/ha (8.0 bu/acre) |

| T2 + T3 | 0.73 t/ha (10.8 bu/acre) |

| T1 + T2 + T3 | 0.87 t/ha (12.9 bu/acre) |

| Source: Brinkman University of Guelph. 2009-2011 SMART data. | |

Fusarium Head Blight

Ontario conditions pose a high risk of fusarium head blight (FHB) in cereal crops virtually every year. In wheat production, fusarium outbreaks result in fusarium damaged kernels and toxins (especially deoxynivalenol, or DON) in the grain, which can make it unfit for human consumption, and in severe cases, unfit for livestock feed. Due to the humid climate in Ontario, and the constant threat of fusarium, use of a fusarium fungicide is an accepted and almost essential practice. Malt barley, or cereal grains grown as hog feed, have similar concerns.

Spraying Basics: Fusarium Control in Wheat

Application of fusarium control fungicides requires specialized nozzles or nozzle combinations to achieve optimum results. Maximizing wheat head coverage requires both proper timing and the best nozzle configurations.

Maximize Spray Coverage of Wheat Heads

The key to applying fungicides to prevent fusarium head blight (FHB) is to spray all sides of all wheat heads with product. Heads that are missed or only partially sprayed are not protected adequately. Many spray nozzles and nozzle combinations to maximize spray coverage on all sides of the wheat heads have been evaluated.

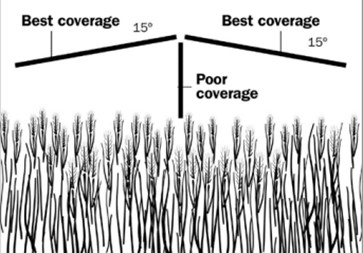

Results showed that the closer the nozzles sprayed to horizontal, in a forward and back manner, the better the spray coverage. Nozzles that spray close to vertical had significantly less spray coverage on the heads. Figure 4–5, Suggested nozzle orientation of a forward-and-back double nozzle assembly, shows a boom-end view of the recommended nozzle orientation of a forward-and-back double nozzle assembly. Turbo FloodJet®[RL(1] [FJ2] nozzles alternating forward and back every 51 cm (20 in.) along the boom also have this 15°-below-horizontal spray inclination. These two nozzle set-ups provide the best spray coverage for FHB control.

Figure 4-5. Suggested nozzle orientation of a forward-and-back double nozzle assembly

Nozzles with a shallow attack angle, such as forward-and-back double nozzles and alternating Turbo Floodjets, have significantly better spray coverage of wheat heads than nozzles spraying straight down.

Water Volumes

Follow label directions. More water should improve spray coverage, especially in windier conditions. For ground application keep water volumes in the 170–190 L/ha (18–20 US gal/acre) (GPA) range. Do not exceed 20 GPA application rates.

Spraying Speed

Spray coverage levels are very near equal from 10–20 km/h. Travel speed does not change the ranking or coverage level of the different nozzles.

Nozzle-to-Target Distance

Forward-and-back double nozzle assemblies and alternating Turbo FloodJets should be operated at 25–30 cm (10–12 in.) above the wheat canopy. Operate other nozzles a sufficient height above the canopy — about 50 cm (20 in.) — to allow full pattern development. Operating nozzles higher than this minimum nozzle-to-target distance will result in a significant reduction in spray coverage. Operating the boom at double the minimum nozzle-to-target distance from the wheat heads could reduce head coverage by as much as 50%.

Application Timing for Fungicides for FHB Control

Day 0 occurs when 75% of the heads on the main stems are fully emerged. Target spray applications for Day 1 to Day 4, with optimum timing being Day 2.

Rain Fastness

Current FHB fungicides are all rainfast in 1 hour. Apply fungicide once wheat heads are fairly dry. Moisture droplets on the heads may cause spray to run off, thereby reducing coverage levels. Updated information can be found in OMAFRA Publication 812, Field Crop Protection Guide.

Sprayer Cleanout Before Spraying Wheat

It is essential to clean out sprayers totally, including boom end caps. Wheat at heading is very sensitive to any tank contamination, with yield loss approaching 100% in severe cases. If sprayer cleanout is not adequate, producers would be better not to spray for FHB.

Fusarium Forecasting

Weather INnovations Incorporated (WIN) offers the DONcast forecast modelling system. Visit the WIN website at www.weatherinnovations.com and follow the prompts.

Fungicides and Crop Maturity

Fungicides help keep plants healthy, which reduces infection by disease. Healthier plants result in higher yields but delay harvest by 2–3 days. Delayed harvest gives the impression that fungicides delay maturity when in fact, fungicides delay premature death brought on by disease. This delay extends the grain fill period and allows the crop to fully mature and results in increased yield.

Fungicide/Nitrogen Interactions

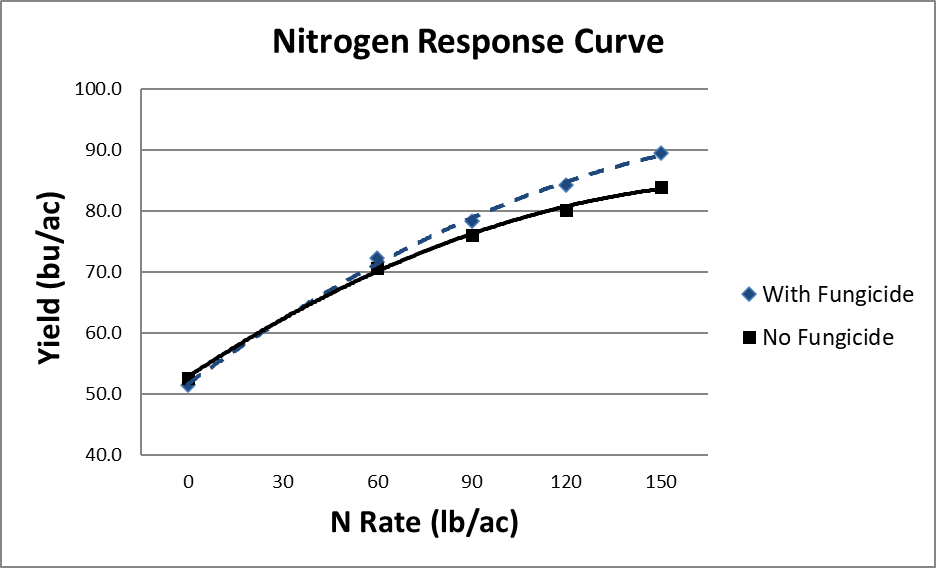

Recent research has shown a synergy between nitrogen and fungicides (Hooker et al, 2014, Johnson and McClure, field data, 2008–2014) in winter wheat. When high nitrogen rates are applied in conjunction with fungicides, yield increases are more than just the additive result of fungicide plus nitrogen as shown in Figure 4–6, Nitrogen response with and without fertilizers. The fungicide keeps the plant healthy, allowing the crop to utilize the higher nitrogen application. This synergistic response is clearly evident in winter wheat, where genetic yield potential and earlier maturity (reduced heat stress) allow better utilization of applied nitrogen. Work is currently underway to determine the extent of this synergy in spring cereals. Initial results in other cereals are not as encouraging.

Figure 4-6. Nitrogen response with and without fungicides

Source: P. Johnson and S. McClure, OMAFRA 2013-2014