Seed Quality

Using high-quality, pedigreed seed from inspected fields is important to promote early season vigour and reduce the risk of seed-borne disease. Bacterial blights, anthracnose and BCMV are seed-borne diseases that cause serious issues in some years.

Most coloured bean seed (except black bean seed) is imported from arid growing regions in the U.S. where there is a low incidence of bacterial blight and anthracnose. Some seed, particularly white and black bean seed, may originate from pedigreed seed production in Ontario. Test all seed for germination. See Appendix F, Ontario Laboratories Offering Custom Seed Germination Testing.

Ensure that seed is free from mechanical injury and weather damage, and be sure to handle seed gently. Bean seeds are fragile and sensitive to rough handling, which can damage the growing point within the seed and result in slow or reduced emergence, distorted growth and missing cotyledons. Seed harvested at less than 16% moisture is more prone to mechanical damage. To reduce damage, minimize the distance seed falls, ideally less than 0.5 m (2 ft), and use brush augers and conveyors rather than regular augers. Poor-quality seed, including mechanically damaged seed, can result in reduced germination and vigour, uneven emergence, stunting or even “bald-headed” plants (plants without true leaves).

Planting Date

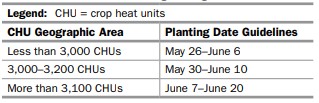

The ideal germination temperature for dry edible beans is 15°C or above. Optimum plant growth occurs between 18°C–23°C. The minimum temperature for growth is 10°C and maximum temperature is 32°C. Table 1, Planting date guidelines, displays the ideal planting dates according to geographic region. The highest yields are obtained by planting within these dates. Refer to Publication 811, Figure 1–1, Crop heat units (CHU-M1) available for corn production, to determine the heat unit rating for your area. Check with the seed distributor for variety-specific planting recommendations.

Table 1. Planting date guidelines.

Dry edible beans are less vigorous than soybeans and must be planted when soil conditions are warm and moist, ensuring quick, uniform emergence. Low temperatures at planting increase the risk of slow emergence, and damage from herbicide injury, soil crusting and root rot. When determining the planting date, temperatures at flowering must also be considered. Planting within the appropriate dates will avoid hot, dry weather during flowering and ensure a timely harvest. Temperatures greater than 32°C can cause “flower blasting” (dropping of buds and flowers). Regardless of planned planting date, it is most important that the soil is fit for planting before proceeding. Under late planting conditions, carefully consider when dry edible beans will mature before continuing to plant. Dry edible beans are less able than soybeans to adapt to a shorter growing season from late planting.

Seeding Rates

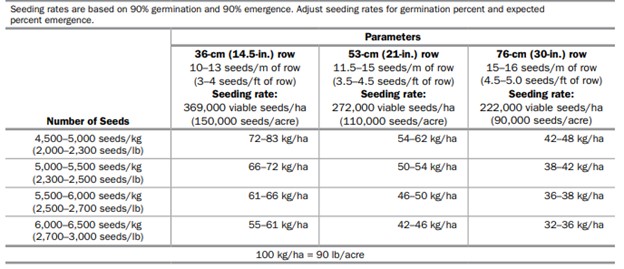

Dry edible bean seed size varies greatly. Check to ensure the planter is calibrated properly to plant the correct number of seeds per metre of row. Adjust seeding rates for seed quality and expected germination rate, field conditions and field history. In conditions where reduced emergence is a risk, increase seeding rates by up to 10%. High-risk conditions include seeding into heavy soil, late or very early planting, deeper plantings or expected seedling loss from wireworm or seed corn maggot injury, and planting into soils susceptible to soil crusting.

Table 2. Seeding rates for white and black beans

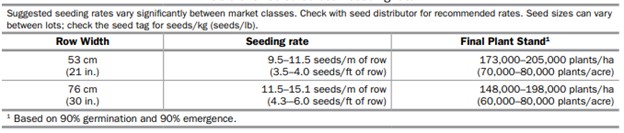

General seeding rate guidelines for coloured beans are shown in Table 3, Coloured bean seeding rate. The average desired plant stand for adzuki beans is 210,000 – 222,500 plants/ha (85,000–90,000 plants/acre), and for otebo is 173,000 plants/ha (70,000 plants/acre). Consult the seed supplier for more specific information on seeding rates for the various classes. Seeding rates may also depend on the type of equipment used for planting.

Table 3. Coloured bean seeding rate

Seeding rate can be calculated using seeds/kg found on seed tag with the following formula:

Seeding rate (kg/ha or lb/acre)

= desired final plant population ÷ seedling survival rate ÷ seeds/kg (seeds/lb)

Example: Cranberry beans

148,000 plants/ha desired population

85% seedling survival

1760 seeds/kg

Seeding rate

= 148,000 ÷ 0.85 ÷ 1760

= 99 kg/ha

Seeding Depth

The seeding depth for dry edible beans is critical for uniform emergence. Frequently, poor stands are the result of not planting into moisture. Planting depth should be at least 1.2 cm (0.5 in.) into soil moisture. Uneven emergence results in uneven maturity. A seeding depth of 4–6 cm (1.5–2.5 in.) is normal, but deeper plantings of up to 9 cm (3.5 in.) may be necessary to seed into moisture. Beans planted deeper are more susceptible to poor emergence and crusting. Some older drills cannot provide accurate depth control. In these situations, a planter may be a better option. Seed drills should have gentle seed distribution devices, depth bands — or depth gauge wheels — and press wheels to ensure uniform seed placement and coverage. High quality, accurate and calibrated seeding equipment is critical to dry edible bean production success. Rolling or packing a field prior to planting helps firm the seedbed and conserve moisture, and can help control planting depth when seeding with a drill. Packing after planting helps level out ridges, pushes down small stones and conserves moisture, but it also makes the soil more susceptible to crusting.

Row Width

Row widths of 70–75 cm (28–30 in.) are standard for both white and coloured beans when the crop will be pulled and windrowed. In fields with a high risk of white mould, wide row widths are preferred to allow more air circulation in the canopy. Narrow row widths of 36–56 cm (14–22 in.) are most suitable if the bean crop will be direct harvested. Ontario row width trials with no-till white beans produced yields 14% higher in narrow row widths, i.e., less than 56 cm (22 in.), compared to wide rows. White and black bean row width trials, done in Michigan (2011–12), compared 15-in. and 20-in. row widths to 30-in. rows. Yields were improved between 4.5%–14% with narrower row width, and with no increase in plant height. In narrow rows, it is important to select white bean varieties with an upright plant type and good tolerance to white mould.

Emergence may be better in wide rows seeded with a conventional corn planter than narrow rows seeded with a grain drill or air seeder. Consider that:

- Drills and air seeders can damage fragile seed.

- Planters are designed to provide more uniform and accurate seed depth placement and better seed coverage.

- Wide rows have more seeds per linear measure to push up through surface crust. For example, 16 seeds/m (5 seeds/ft) of row in wide rows, compared to 10 seeds/m (3 seeds/ft) of 36-cm (14 in.) rows.

- Planting seeds into tire tracks can result in emergence problems.

In narrow rows, emergence can be a problem for beans planted into tractor tire tracks. Some producers adapt equipment to harrow or cultivate between the tractor tires and the planter. The advent of rod pullers has enabled beans planted in 50–56-cm (20–22-in.) rows to be pulled and windrowed.

Inoculation

The species of rhizobia for dry edible beans is Rhizobium leguminosarum biovar phaseoli. Dry edible beans are less efficient at fixing nitrogen through rhizobia than soybeans or other legumes. Inoculation trials and routine use of an inoculant have not shown an economic advantage in Ontario, even though other regions do suggest inoculant use for virgin dry edible bean fields.

Dealing with Soil Crusting

Pounding rains from thunderstorms can result in severe crusting on heavy soil types, or soils with poor aggregate stability, and can inhibit bean emergence, particularly if hot, dry conditions bake the soil surface. Soil loosening and aeration may be required. There is no advantage to waiting once the crust has been identified. Waiting may increase the lack of uniformity of the stand. It may be better to have a lower, more uniform stand, than an uneven stand with a higher population. Rotary hoes, culti-packers, coulter-carts, no-till drills, planters and harrows have all been used successfully (and unsuccessfully) in breaking crusted soils.

Typically the rotary hoe can reduce bean stands by 5%–10%, but the extra beans that emerge more than compensate for this reduction. Rotary hoeing during the “hook” stage of bean emergence will result in significant plant losses. Rotary hoeing during mid-day, when bean plants are more flaccid, or limp, will reduce plant damage. Target speed is 10–20 km/h[S1] . Adjust the equipment over a short distance and check that the percentage of bean plants buried or uprooted is less than 10%. It is normal for the crop to look a little “tough” following rotary hoeing. Weed control will also be enhanced when uprooted weeds dry out in mid-day heat.

Stand Assessment and Replant Decisions

The decision to replant can be one of the most difficult decisions for a producer to make. Stresses on the crop are additive and typically have a greater impact on dry edible beans than soybeans. An adequate stand of dry edible beans is a minimum of two-thirds to three-quarters of a full stand. Dry edible beans have a limited ability to branch and compensate for stand losses.

Beans which germinate, but are slow to emerge, will often develop a thickened hypocotyl (stem), leaf out underground, or develop seedling blight. When injury has been identified, flag a few areas in a field to monitor and reassess. Check the root system for new growth and for discolouration caused by root disease; the roots should be bright white. Compare the growth in injured areas to growth in unaffected areas. Consider that additional weed control and/or desiccants may be needed where plant stands are uneven.

Before replanting, consider the cause of the poor stand, the remaining population of healthy plants, plant uniformity, weed control needs and the date of replanting. Cranberry beans generally perform better under late planning scenarios than white beans or other coloured beans.

Minimum number of healthy plants in the row should be:

6.5-8 plants/m (2–2.5 plants/ft) of row in 38–56 cm (15–22 in.) rows

10-13 plants/m (3–4 plants/ft) of row in 76 cm (30 in.) rows

5-6.5 plants/m (1.5–2 plants/ft) of row in 18 cm (7 in.) rows

These numbers are based on good growing conditions, the good health of the remaining plants, a uniform stand and uncompacted soil.

[S1]Add imperial

CB: not for speed