This article was written by Jonathan Sawicki, a summer research assistant with OMAFA assisting with corn research and extension projects during the summers of 2023 and 2024. Jonathan is now an M.Sc. candidate in the School of Environmental Sciences at the University of Guelph.

This article discusses the challenges Ontario agriculture faced in 2024 due to high soil moisture levels during planting and the early growing season, which led to soil compaction, especially in approaches and headlands (Fig. 1). Some traditional methods to prevent soil compaction include minimum or zero tillage, controlled traffic, increased organic content, and deep ripping. These methods help prevent compaction, but they do not provide long-term fixes for compaction that has already happened. It could be worth exploring the benefits and risks of potential compaction solutions researched or used in other parts of the world such as injecting biochar or natural polymers with pneumatic soil fracturing.

What is Compaction and Why Does It Matter?

Throughout the spring and early summer of 2024, Ontario had quite wet soil conditions, which made things tough for farmers. The 2024 growing season saw planting dates all over the place, problems drying hay, soil smearing, and a greater risk of soil compaction. When soil is compacted, it becomes denser and makes it hard for air, water, and roots to move through, affecting soil structure, access to nutrients, plant health, and yields. It is essential to deal with these challenges to keep the soil healthy, help crops grow well, and support sustainable land management. This report investigates alternative solutions for dealing with compacted soils, like pneumatic soil fracturing, especially in compaction prone areas like headlands and field approaches.

Soil Compaction Issues:

– High moisture levels are a concern for farmers.

– Techniques to reduce compaction risks include minimum or zero tillage, controlled traffic, and combining farm operations with the same machine to minimize passes.

– Deep ripping can loosen compacted soil temporarily but does not address the root causes of compaction.

– Increasing soil organic matter through various methods is crucial to reducing soil bulk density and acting as a buffer against compaction transmission to the subsoil.

– Preventing compaction from occurring in the first place is best, but not always possible.

The abnormally high moisture levels in 2024 were a significant concern for producers (Fig. 2). Many well-known techniques reduce compaction risks, including implementing minimum tillage (or zero tillage), controlled traffic, and combining farm operations with the same machine to minimize the number of passes (Hamza & Anderson, 2005). Other practices include loosening compacted soil through deep ripping (usually a temporary effect), incorporating deep-rooted plants into rotations, and using machines with low axle loads and tires with low inflation pressures and high surface contact area to minimize ground pressure (Hamza & Anderson, 2005). Deep ripping is considered a temporary effect because although it loosens the compacted soil, it can become compacted again when driven upon. The process breaks up the soil but does not address the root causes of compaction, so the soil may return to its compacted state with continued use and traffic. Therefore, while deep ripping can provide short-term relief from compaction, it is not a long-term solution.

Additionally, increasing soil organic matter through stubble retention, green and brown manure, or adding plant or animal organic matter from external sources is crucial to reducing soil bulk density and serving as a buffer against compaction transmission to the subsoil from external loads acting on the topsoil (Kozlowski, 1999). Dealing with compaction is essential, and one of the best ways to address it is by preventing it from occurring in the first place. However, it is not always avoidable.

Potential Compaction Solutions

Pneumatic Soil Fracturing

– Pneumatic soil fracturing is a method used to improve soil structure and permeability.

– It involves the injection of high-pressure air into the soil to create fractures and fissures.

– This process can help alleviate compaction and enhance root growth in agricultural landscapes.

– Pneumatic soil fracturing is considered an alternative to traditional mechanical methods of soil loosening.

– Like deep ripping, it is not a long-term solution.

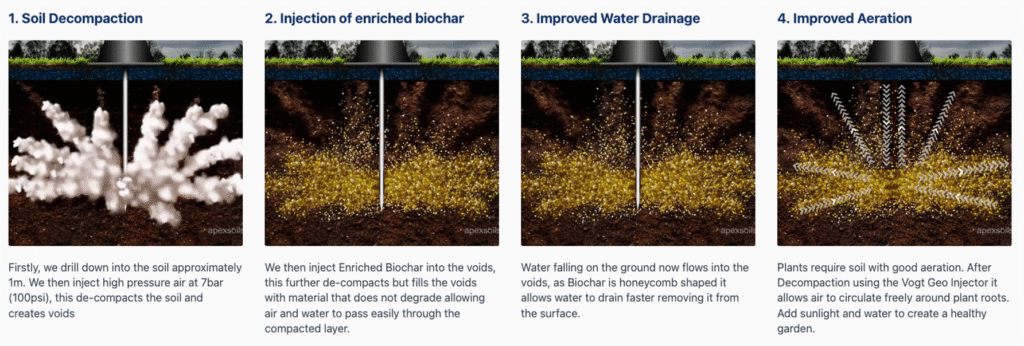

Pneumatic soil fracturing is a technique used to alleviate soil compaction. It involves the injection of high-pressure air into the soil to fracture compacted layers, thereby improving soil structure and potentially reducing soil bulk density (Smiley, 2001). This process helps to enhance water infiltration, root growth, and access to soil nutrients (Smiley, 2001). Additionally, pneumatic soil fracturing can promote better aeration and drainage, ultimately contributing to healthier soil conditions for plant growth (Schuring et al., 1991). Pneumatic soil fracturing is a temporary solution and often produces variable results, but adding injected biochar and natural polymers may provide more consistent, longer-lasting results (Smiley, 2001).

What Is Biochar and What Does It Do?

– Biochar, produced through pyrolysis of organic materials, can be injected after soil fracturing to enhance soil structure and allow better water, air, and nutrient flow.

– The quality of biochar feedstocks is crucial, and contaminated feedstocks can introduce toxins and inhibit plant growth.

– The rate and composition of biochar addition can significantly impact crop growth, production, and soil organisms, so careful consideration is essential.

– Inject biochar after soil fracturing to fill pores and help maintain improved soil structure.

– Ensure clean feedstocks with high lignin content to avoid introducing toxins into the soil.

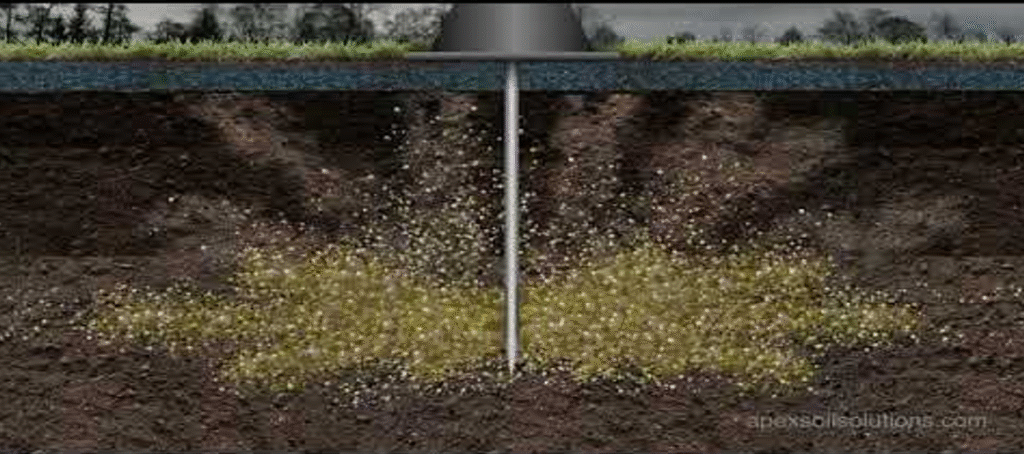

Biochar is a substance similar to charcoal, created by burning organic materials from agricultural and forestry wastes, also known as biomass, in a controlled process called pyrolysis (Spears, 2018). Although it may resemble ordinary charcoal, biochar is produced using a specific process to reduce contamination and effectively store carbon (Spears, 2018). In pyrolysis, organic materials such as wood chips, leaf litter, or dead plants are burned in a container with minimal oxygen, releasing minimal to no contaminating fumes (Spears, 2018). Through this process, the organic material is converted into biochar, a stable form of carbon that is securely stored and less likely to escape into the atmosphere (Spears, 2018). When injected after soil fracturing (Figs. 3 and 4), it fills the newly created pores and helps maintain the improved soil structure (Liu et al., 2017). Biochar is naturally porous, allowing water, air and other nutrients to flow better through the soil profile. Mycorrhizal fungi, Trichoderma, wormcasts and seaweed, among others, can be injected into the soil along with the biochar with minimal surface soil disruption to improve soil health and structure. (Liu et al., 2017)

It is important to remember that the quality of the materials burned, or feedstocks, directly affects the quality of the final biochar product (Spears, 2018). It is ideal to use clean feedstocks with 10 to 20 percent moisture and high lignin content, such as field residues and woody biomass (Spears, 2018). Using contaminated feedstocks, such as those from railway embankments or contaminated land, can introduce toxins into the soil, increase soil pH, and inhibit plants from absorbing minerals (Spears, 2018). The most common contaminants are heavy metals like cadmium, copper, chromium, lead, zinc, mercury, nickel, arsenic, and polycyclic aromatic hydrocarbons (Spears, 2018). The biochar addition rate significantly affects crop growth and yield, but the impact varies based on the farming system and crop type (Semida et al., 2019).

Additionally, the composition of biochar can influence plant growth, production, and soil organisms (Semida et al., 2019). In some instances, it can increase soil microbial composition, while in others, it can have toxic effects (Semida et al., 2019). Therefore, it is essential to carefully choose the composition and rate of biochar and ensure its compatibility with the crop and cropping systems (Semida et al., 2019). Biochar has the potential to greatly benefit crop production, whether in large-scale field production or greenhouse pot production. Using quality source materials and using the 4-Rs biochar can pose little risk to crops and the environment.

Figure 4. Pneumatic soil fracturing and biochar injection (from Apex Soil Solutions).

Hydrogels and Natural Polymer Injection

– Potential use of natural polymers and hydrogels to reduce soil compaction and improve soil health

– Hydrogels are made from hydrophilic, crosslinked polymers and can absorb and retain large amounts of water

– Applications of hydrogels include enhancing soil quality, retaining water, promoting seed germination and seedling growth, and preventing soil compaction

– Natural polymers differ from plastic polymers and can improve oxygen accessibility in the plant root zone, enhance microbial activity, and improve soil physical properties

– Further research is needed to understand the environmental impacts and biodegradation of these materials in agricultural contexts

Various natural polymers and hydrogels are potential substances that can help reduce compaction and improve soil health. Prefacing, use, and understanding of these materials are in their early stages and require further research to comprehend their environmental impacts (Oladosu et al., 2022). Hydrogels are materials made from hydrophilic, crosslinked polymers that form three-dimensional networks capable of absorbing and retaining large amounts of water. Agricultural hydrogel enhances soil quality, retains water, and helps plants withstand drought (Almajed et al., 2022). It promotes improved seed germination and seedling growth, establishes a continuous cycle for delivering water directly to roots, and helps prevent soil compaction (Almajed et al., 2022).

Natural polymers differ from plastic polymers; they have the potential to be biodegradable and easier on the environment. They help by improving the accessibility of oxygen in the plant root zone and enhancing microbial activity, which allows crops to withstand permanent wilting and excess moisture stress better (El-Rehim et al., 2004). In addition, they improve various physical properties of the soil, such as porosity, bulk density, water holding capacity, permeability, and infiltration rate (El-Rehim et al., 2004). Polymer biodegradation is a rapidly evolving area of research. However, its connection with polymer applications in soil within an agricultural context is still emerging in the literature. Further understanding of their impact must be understood to see if their implementation is suitable for Ontario agriculture.

Several instances of pneumatic soil fracturing practices exist primarily in the turf grass industry, landscaping, and small-scale practices. Research on the benefits of these practices still needs to be done in Ontario’s agriculture sector. Could adding biochar or polymers and pneumatic soil fracturing help reverse and prevent compaction in areas such as headlands and approaches?

What About Rubber?

– A study in Asia used granulated tires mixed into the soil to address compaction

– Adding 0.8 – 1.0 mm crumbed rubber to soil reduced bulk density

– Decreased penetration force and increased water permeability confirmed reduced compaction

– Concerns exist about the release of zinc oxide and potential microplastic issues

– A long-term study is needed to assess the impact on soil properties and toxicity levels

– Evaluation of toxicity levels below acceptable thresholds would be necessary before considering crumbed rubber for alleviating compaction in Ontario agriculture

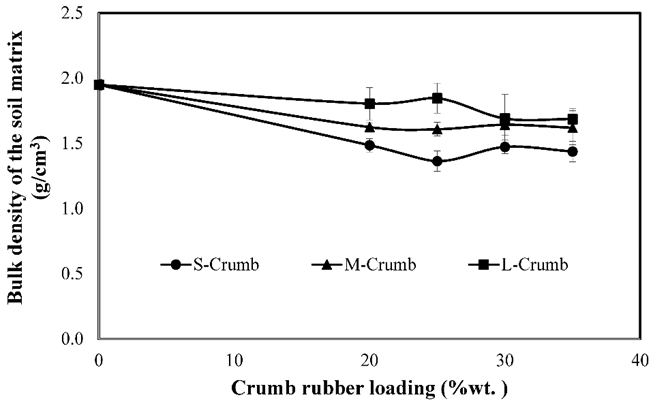

Furthermore, a promising study completed in Asia using granulated tires mixed in the soil profile to alleviate compaction and reduce the hardpan showed promising results. Adding crumbed rubber, 0.8 – 1.0 mm in size (s-crumb) to the soil profile resulted in a significant reduction in bulk density, as seen in Figure 5 (Sirichai Pattanawanidchai et al., 2023). A significant decrease in penetration force and a considerable increase in water permeability confirmed decreased soil compaction (Sirichai Pattanawanidchai et al., 2023). However, it is essential to consider issues related to the potential release of pollutants such as zinc oxide from the rubber and microplastic concerns before implementation (Sirichai Pattanawanidchai et al., 2023). Hence, a long-term study on the impact of crumb rubber addition on soil properties and toxicity is necessary to evaluate its impacts and effectiveness in Ontario agriculture. Suppose the results of a long-term study showed that the toxicity levels were below acceptable thresholds. Would adding crumbed rubber to approaches and headlands be a potential way to alleviate compaction issues in Ontario?

Summing It Up

Throughout the spring and early summer of 2024, Ontario experienced consistently high soil moisture levels, posing many challenges for producers. Addressing soil compaction is crucial for maintaining soil health and ensuring optimal crop growth. While prevention is the best approach, alternative solutions such as pneumatic soil fracturing, biochar injection, and polymers and hydrogels may help mitigate the effects of soil compaction and improve soil conditions. Researchers and producers must assess these techniques’ viability, risks and potential impact in their agricultural settings. Additionally, ongoing research and development in this field are essential for identifying and refining effective soil compaction resolutions. This report provides a foundation for understanding potential strategies for managing soil compaction, acknowledging that further study and site-specific analysis are necessary for successful implementation.

References

Almajed, A., Lemboye, K., & Moghal, A. A. B. (2022). A Critical Review on the Feasibility of Synthetic Polymers Inclusion in Enhancing the Geotechnical Behavior of Soils. Polymers, 14(22), 5004. https://doi.org/10.3390/polym14225004

El-Rehim, H. A. A., Hegazy, E.-S. A., & El-Mohdy, H. L. A. (2004). Radiation synthesis of hydrogels to enhance sandy soils water retention and increase plant performance. Journal of Applied Polymer Science, 93(3), 1360–1371. https://doi.org/10.1002/app.20571

Hamza, M. A., & Anderson, W. K. (2005). Soil compaction in cropping systems. Soil and Tillage Research, 82(2), 121–145. https://doi.org/10.1016/j.still.2004.08.009

Improve Soil Health with an Enriched Biochar Injection from Apex. (n.d.). Apex Soil. Retrieved July 22, 2024, from https://apexsoilsolutions.com/what-is-biochar/

Kozlowski, T. T. (1999). Soil Compaction and Growth of Woody Plants. Scandinavian Journal of Forest Research, 14(6), 596–619. https://doi.org/10.1080/02827589908540825

Liu, Q., Liu, B., Zhang, Y., Lin, Z., Zhu, T., Sun, R., Wang, X., Ma, J., Bei, Q., Liu, G., Lin, X., & Xie, Z. (2017). Can biochar alleviate soil compaction stress on wheat growth and mitigate soil N2O emissions? Soil Biology and Biochemistry, 104, 8–17. https://doi.org/10.1016/j.soilbio.2016.10.006

Oladosu, Y., Rafii, M. Y., Arolu, F., Chukwu, S. C., Salisu, M. A., Fagbohun, I. K., Muftaudeen, T. K., Swaray, S., & Haliru, B. S. (2022). Superabsorbent Polymer Hydrogels for Sustainable Agriculture: A Review. Horticulturae, 8(7), 605. https://doi.org/10.3390/horticulturae8070605

Schuring, J. R., Valdis Jurka, & Chan, P. C. (1991). Pneumatic fracturing to remove VOCS. Remediation, 2(1), 51–68. https://doi.org/10.1002/rem.3440020106

Semida, W. M., Beheiry, H. R., Sétamou, M., Simpson, C. R., Abd El-Mageed, T. A., Rady, M. M., & Nelson, S. D. (2019). Biochar implications for sustainable agriculture and environment: A review. South African Journal of Botany, pp. 127, 333–347. https://doi.org/10.1016/j.sajb.2019.11.015

Sirichai Pattanawanidchai, Pongdhorn Sae-Oui, Thipjak Na-Lumpang, Surapich Loykulnant, & Thirapong Kuankhamnuan. (2023). Reduction in Soil Compaction by Utilization of Waste Tire Rubber. Sustainability, 15(16), 12174–12174. https://doi.org/10.3390/su151612174

Smiley, E. T. (2001). TerraventTM: Soil Fracture Patterns and Impact on Bulk Density. Arboriculture & Urban Forestry, 27(6), 326–330. https://doi.org/10.48044/jauf.2001.036

Spears, S. (2018, May 16). What is Biochar? Regeneration International. https://regenerationinternational.org/2018/05/16/what-is-biochar/