Residue management impacts the quantity, location, and distribution of plant material left in a field, both on top of and within the soil. It includes factors such as harvest, tillage, and crops grown. Sound residue management is a critical component to success in field crop production, especially in reduced tillage systems. This factsheet focuses on residue management at crop harvest.

Importance of Residue Management

Plant residue protects soil from erosive and other forces of degradation, reduces soil moisture loss, and contributes to soil organic matter and nutrients. Residue on the soil surface increases soil water infiltration and reduces risk of surface crusting. On the other hand, high levels or unevenly distributed crop residue slows soil warming and drying in spring, which can pose a challenge, especially on clay-based soils. Crop residue can also negatively impact seed placement and host certain pests and diseases. Effective crop residue management improves uniformity of soil fitness across the field and improves seedbed condition; it may also lessen pest pressures on subsequent crops.

Residue management starts during harvest. The harvester is a key component of residue management to process the crop and evenly spread residue across the soil surface. Effective residue management at harvest is critical to the following crop’s establishment and growth.

Header Processing

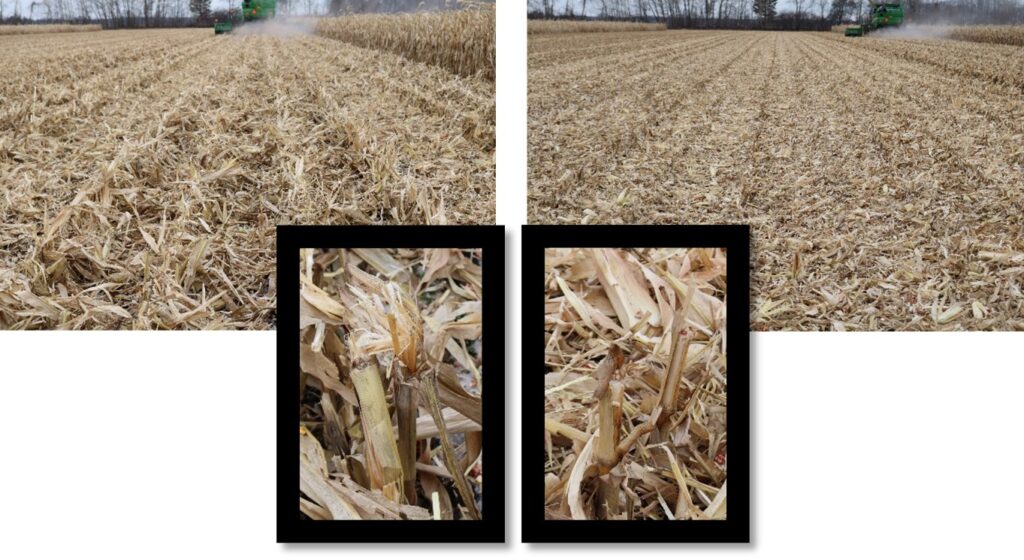

Combine headers can be outfitted with different methods for residue processing. On corn headers there are a variety of stalk rolls that process residue to varying degrees. Some lacerate and crush the stalks and others are gentler – crimping stalks or even leaving stalks standing or leaning. Depending on processing, corn stalk decomposition rate will vary and impact the seedbed for the subsequent crop. For example, in a no-till soybean crop following corn, an operator may want to leave stalks more upright and less processed (Figure 1, left) to minimize surface residue interference with soybean seeding. Matted or flattened residue hampers soil surface drying and may delay planting in wet springs. In a tillage-based system, more aggressive stalk processing may be beneficial (Figure 1, right). Chopping headers are equipped with knife rollers on the row units or a chopping blade underneath to cut stalks into smaller pieces as they are pulled through. Aftermarket attachments such as stompers or stalk rollers (Figure 2) can perform added residue processing on stalks below cutting height.

Figure 1. Non-chopped (left) vs. chopped corn stalks.

Figure 2. Close up of stalk rollers underneath a corn header (Yetter Stalk DevastatorTM).

In some regions, stripper headers are used to reduce the volume of residue to be processed by the combine. Leaving stalks standing and only removing grain heads prevents the need for spreading straw. Figure 3 shows an example of wheat harvested by stripper header in Ontario.

Figure 3. Seeding into standing wheat stalks following harvest

by a stripper header. Photo: Adam Rose.

Combine Discharge and Residue Spread

Crop residue should be spread uniformly over the entire width of the header. Inherent properties of crop residue can impact the effectiveness of spread. For example, combines discharge both straw and chaff. The straw is what passes through threshing and separating units and contains larger materials, whereas chaff comes off the cleaning system and contains light, small pieces of residue. Combine setup is critical to achieving an even distribution of both chaff and straw, as chaff is generally more difficult to throw great distances than straw.

Width of header poses an added challenge. Combines can struggle to achieve an even residue spread over the full width of wide headers. For narrow headers, spread pattern should be adjusted to avoid overlapping.

Certain issues with uniform residue spread can start further within the combine if residue is fed unevenly into the combine chopper and spreading attachment, or if knives are worn out and dull. Issues within the combine may be identified as heavier strips of residue in the spreading pattern. Single rotor combines tend to bias the chopper feed to one side, which requires vanes to deflect material more evenly into the chopper; adjustment and regular maintenance of these vanes is important.

Residue spread out the back of the combine is critical as well. Tailboard vanes can be adjusted and should be free of residue to achieve an even pattern. Tailboards have been replaced by powered tailboards or spreaders for wider spread patterns. More recent combine models have residue chopping and spreading attachment options that enable uniform residue distribution even at wide header widths. They can still, however, be impacted by environmental factors such as wind (Figure 4). Some modern systems have compensation built in to adjust for wind; while certain ones are fully automatic, others require manual intervention to set the amount and direction of bias to the spread pattern. These wind compensation systems need to be monitored to ensure spread pattern is consistent throughout changing weather conditions.

Figure 4. Wind negatively affecting evenness of residue spread.

Residue Removal

Another option for residue management is to remove it. A portion of crop residue could be removed after harvest for animal bedding or biomass processing. This is a common practice for small grains, but less so for grain corn and soybeans. Residue removal can lessen challenges such as delayed soil drying but leaves less residue to help maintain soil organic matter and protect soil, which is of particular concern for low-residue crops like soybean. It also removes valuable soil nutrients such as phosphorus and potassium. Consider these impacts when removing straw and other crop residues.

Acknowledgements

Thank you to Alex Barrie, Danny Jefferies, and Colin Elgie for their contributions to this factsheet.