Manure and organic amendments contain two main forms of nitrogen (N): organic nitrogen and ammonium nitrogen (NH4-N). The nitrate nitrogen (NO3-N) in manure is negligible, however the ammonium portion in manure is converted to nitrate within weeks of application during the growing season. NH4-N and NO3-N are immediately available to a growing crop, similar to nitrogen from mineral fertilizer.

Ammonium N and volatilization

Although the ammonium N (NH4-N) is available quickly to plants it is also subject to rapid volatilization loss to the air as ammonia (NH3-N) gas. The volatilization process continues until the manure is moved into the soil by incorporation or gentle rainfall. Manure that has a high proportion of NH4-N (generally liquids) and if injected or incorporated quickly, will provide more nitrogen for the crop.

Volatilization loss will not affect the organic N portion of the manure. Table 1 shows the proportion of Ammonium N, with the remainder as organic N. Solid manure has a much lower proportion of NH4-N, and therefore comparatively lower N loss.

Table 1. Approximate ammonium-nitrogen as a percentage of total nitrogen in various manure types

| Type | Source | Ammonium-N (NH4-N)2 |

| Liquid manure1 (0-15% DM) | Liquid hog | 66 % |

| Liquid dairy | 45 % | |

| Liquid beef | 42 % | |

| Liquid poultry | 69 % | |

| Anaerobic digestate | 52 % | |

| Solid manure1 | Solid hog | 27 % |

| Solid dairy | 18 % | |

| Solid beef (high bedding) | 17 % | |

| Solid horse | 10 % | |

| Solid poultry (broilers) | 21 % | |

| Solid poultry (layers) | 30 % | |

| Compost (mature) | 3.5 % | |

| Municipal sources | Aerobic sewage biosolids | 15 % |

| Anaerobic sewage biosolids | 35 % | |

| Lystegro | 41 % | |

| Dewatered sewage biosolids | 17% | |

| Biosolids pellets | 6 % | |

| Ashed biosolids | < 1 % | |

| Spent mushroom compost | 6.5 % | |

| 1 Ammonium content increases as moisture content increases (or dry matter decreases) 2 Balance of nitrogen is in organic-N form. Data compiled from AgriSuite 2024 | ||

The rate of potential NH4-N loss will depend on the manure pH, temperature, soil moisture, crop residue and wind conditions at the time of and following application. Hot, dry, and windy conditions are most conducive for volatilization losses. Moist soils increase the opportunity for ammonium to be absorbed into the soil water. Microbial activity is lower in cold soils, slowing down the conversion of ammonium to ammonia.

In many instances, high crop residue can help reduce ammonia loss. Crop residue can act as a physical barrier and help reduce manure exposure to air, thereby trapping ammonia. In addition, increased microbial activity and soil moisture in high residue fields can further reduce volatilization losses.

Manure pH has a significant role in ammonia loss. Ammonia loss from manure increases significantly as the pH rises above 7. When pH is high, more of the nitrogen is in ammonia form, while below pH 7 the ammonia is converted to ammonium. Modifying livestock diets and manure acidification (e.g., using sulfuric acid) are methods currently being explored to reduce methane production in manure storages and reduce nitrogen loss from applied manure.

Considering temperature, soil moisture, pH, residue or crop cover and time to incorporation, Table 2 provides the estimated portion of ammonium N that will be retained for the crop in the year of application. For manure applied later in the fall, when temperatures fall below 10oC, ammonium losses are lower since cooler temperatures slow down microbial activity in soil and slows conversion to ammonia.

Table 2. Estimated proportion (factor) of ammonium nitrogen from manure retained in the year of application

| Incorporation Details | Injected (covered) | Incorporated | Not Incorporated | ||||||

| 1 day | 2 days | 3 days | 4 days | 5 days | Bare Soil | Residue | Standing Crop (below canopy) | ||

| Average (factor) | 1.00 | 0.75 | 0.60 | 0.50 | 0.45 | 0.40 | 0.35 | 0.50 | 0.66 |

| Cool (<10oC)1 | 1.00 | 0.85 | 0.70 | 0.60 | 0.55 | 0.50 | 0.45 | 0.66 | 0.75 |

| Warm (>25oC)1 | 1.00 | 0.65 | 0.50 | 0.40 | 0.35 | 0.30 | 0.20 | 0.35 | 0.55 |

| Adapted (K Reid) from Dr J Lauzon, K Janovicek, U. of Guelph 2013. The table is based on an evaluation of data from 180 field sites which measured crop yield response to manure, of which 165 recorded grain yields. 1 Shows a trend for ammonia loss under cooler or warmer than average temperatures. Other factors such as soil moisture, residue cover and wind speed will also affect ammonia retention. | |||||||||

Available organic N from manure and other organic amendments

Organic nitrogen is derived from organic matter and includes the nitrogen compounds such as proteins and amino acids that are bound to carbon. Organic nitrogen from manure is not immediately available to plants. It must be converted to ammonium or nitrate by soil microorganisms. This mineralization process is gradual and provides plant available nitrogen over several years.

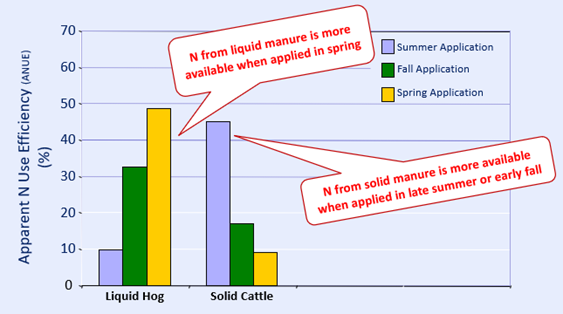

Since liquid manure generally has higher NH4-N, it will provide the maximum crop N efficiency when applied in the spring. Solid manure is higher in organic N and requires time for microbial activity. Fall application (ideally with cover crops) will provide time for mineralization and maximum crop N efficiency for the subsequent crop. This is illustrated in figure 1 for liquid hog and solid cattle manure.

The amount of organic N and how quickly it can be mineralized will vary with:

Livestock species

Monogastric livestock (hogs, poultry) have a single stomach and are fed grain-based diets that are easier to digest and results in manure with higher readily available nutrients – especially nitrogen. Ruminant livestock (cattle, sheep, goats) have 4-chambered stomachs that digest mainly forage-based diets through fermentation. Manure from ruminants has higher solids and higher viscosity.

Stage of production

Young rapidly growing livestock, as well as livestock and poultry producing milk, meat or eggs will have more nutrient dense rations than livestock in maintenance stages (e.g., cows in high milk production vs dry cows). High protein diets produce manure with higher nitrogen content. In solid manure most of the nitrogen is in the organic form. How quickly it becomes available depends on the carbon to nitrogen ratio (C:N)

Bedding materials

The amount and type of bedding will affect the availability of organic nitrogen in manure. Straw bedding (C:N =~ 80:1) will break down more quickly than wood chip bedding (C:N =~200:1). C:N provides an indication of how much nitrogen is in the manure that the microorganisms can utilize as they break down the carbon. The higher the C:N the longer it takes for the organic nitrogen to become plant available.

C:N ratios and organic N

When an organic amendment is applied to a field, it adds nutrients and organic matter to the soil. Table 3 shows the approximate C:N ratio of common organic materials. The carbon: nitrogen (C:N) ratio shows the proportion of organic carbon to total nitrogen of the manure or organic material.

Nitrogen is a food source for the soil micro-organisms while they break down the carbon material. When the process is complete, the soil microbes die and decompose. The microbial nitrogen is then returned to the soil and becomes available to the plants. This is considered the “organic nitrogen” component of the organic materials. How long this process takes depends on the ratio of carbon to nitrogen in the material.

Liquid hog manure has a C:N ratio ranging around 4:1. The organic nitrogen in liquid hog manure will become quickly available when the soil microbes are active in the soil. Horse manure with a lot of straw bedding could have a C:N ratio of over 50:1 while poultry manure, which is high in nitrogen and often bedded with wood shavings could have a C:N ratio near 8:1.

In contrast, pulp and papermill biosolids have a C: N ratio ranging from 25:1 to over 200:1. The nitrogen contribution from this material could take considerably more than one growing season to become available. To compensate for the high C: N ratio, some pulp and paper processors will add nitrogen to balance the carbon and reduce the C:N ratio down to about 25:1.

The C: N ratio of soil is about 10:1.

When solid manure or other organic material has a C:N ratio of greater than 25:1, there is a higher risk that the soil micro-organisms will “steal” nitrogen from the soil and tie it up as they break down the carbon. This makes the nitrogen unavailable to a crop. A crop with higher nitrogen requirements, such as corn or wheat, will show nitrogen deficiencies in that situation. When a material has a C:N ratio less than 20:1, there is generally enough nitrogen in the organic material to break down the carbon without causing a nitrogen deficiency in the crop.

Table 3. Carbon:Nitrogen Ratio of Various Organic Materials

| Material | C:N Ratio Range |

| Soil Microbes | 4:1 to 9:1 |

| Soil Organic Matter | 10:1 to 12:1 |

| Solid Cattle Manure | 20:1 (light bedding) to 40:1 (heavy bedding) |

| Horse Manure | 27:1 (straw bedding) 60:1 (sawdust bedding) |

| Solid Poultry Manure | 5:1 layers 10:1 broilers and turkeys |

| Liquid Hog Manure | < 8:1 |

| Liquid Dairy | 15:1 |

| Legume Residues | 20:1 to 30:1 |

| Corn Stalks | 80:1 |

| Wheat Straw | 80:1 |

| Sawdust | 500:1 |

| Pulp & Paper biosolids | 25:1 (nitrogen added during process) to 200:1 (little or no nitrogen added) |