Direct combining is the most common method of harvest in Ontario, followed by swathing, which still occurs in some areas. Direct combining usually results in improved seed quality compared to swathing, due to fewer fines and less green seed. Direct harvesting is most successful when the crop ripens evenly, is heavy, relatively free of Alternaria disease, and is partially lodged and well knitted together. These conditions also reduce the risk of shattering and pod drop due to wind or driving rain.

The optimum time to harvest canola is when there are fewer than 2% green seeds and seed moisture content is 10% or less. Grain cannot be delivered to end users above 10% moisture. Depending on weather conditions, seeds rapidly lose moisture at 1%–3% or more per day. Many operators start combining when the seed is slightly above 10% moisture because moisture will drop through the day if conditions are hot and dry. Do not delay harvest as seed losses from pod shattering increase dramatically about 10 days after optimum harvest timing. Shattering losses can be reduced by combining at higher seed moisture content and drying the crop, although not all producers have canola drying capacity. If the canola is lodged or leaning, harvesting in the direction of the lean will reduce shatter losses significantly. If the field is weedy or crop maturity is uneven, application of a pre-harvest herbicide can improve ease of harvest and reduce harvest losses.

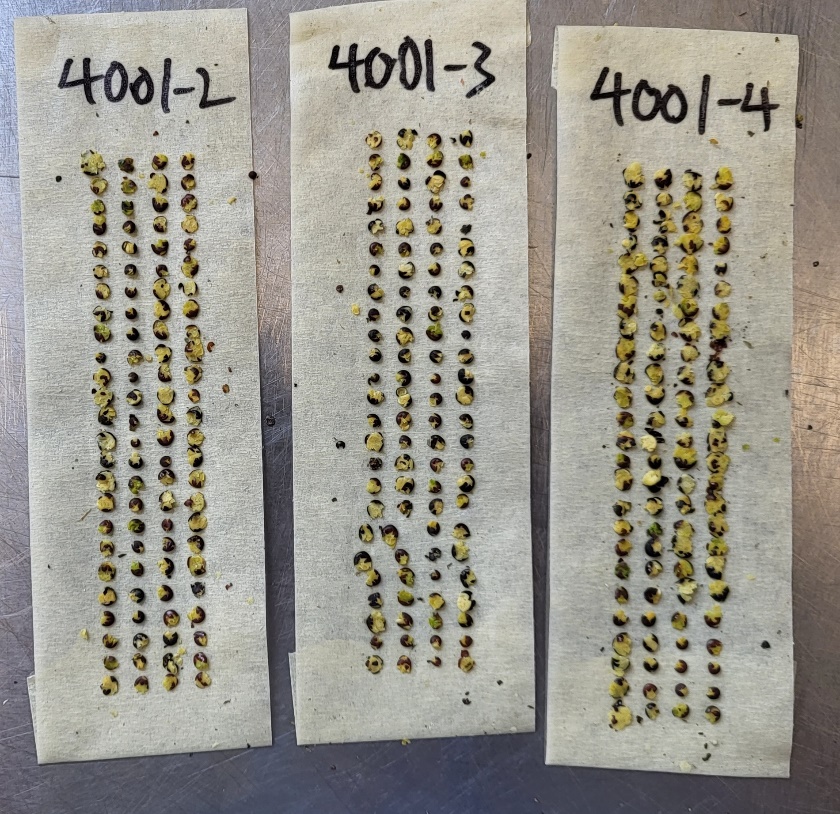

Green seed issues occur when chlorophyll is not degraded or cleared from within the seed. Check harvested samples by crushing seeds on a strip of paper (Figure 1) and determining the percent of distinctly green seeds. No. 1 and No. 2 Canada canola grades may contain a maximum of 2.0% and 6.0% of green seeds, respectively. Hot or windy weather can result in seed moisture content that indicates it is harvest ready, before there has been sufficient time for green chlorophyll to disappear. Several dews or a light rain can help to clear the green colour from seed.

Figure 1. A crush test strip of 100 seeds, used to check for seed that is distinctly green inside. Tools can be purchased to conduct this test. Photo: E. Page.

Monitor and make adjustments throughout the day to minimize harvest losses. 54 seeds/m2 (5 seeds/ft2) on the ground equates to a loss of 1 kg/ha (0.9 lb/acre). Average harvest losses range from 10–50 kg/ha (9–45 lb/acre). Harvest losses tend to be lower at higher ambient temperatures, lower relative humidity, during sunnier conditions and at slower ground speeds. The harvest sample should not be completely free of chaff and residue (Figure 2). A completely clean harvest sample is an indication that there are significant harvest losses going out the back of the combine.

Figure 2. Typical harvest sample.

Harvesting canola can be a slow process. Stems are often somewhat green at harvest, and canola at low populations will have thick stems. Patience is required while waiting for canola to dry down sufficiently, and during harvest.