The storage and handling of livestock feeds in the ensiled form has several advantages. These, however, can only be fully realized if producers select the type of storage structure (silo) most suited to their farm situation. It is important to think of each part of the feed handling picture, from field to feed bunk, as a total feed handling system. This means that each segment (each piece of equipment, storage structure, etc.) must be chosen with the whole operation in mind, so that it fits well with every other segment to make the total the most effective, efficient combination possible. No one part should be allowed to create a bottle-neck in the system.

A silo is more than just a structure to hold a harvested crop in one place until it is needed for livestock feed. Its most important function is to provide the right environment for a proper ensiling process to take place, thereby minimizing feed loss and making a high percentage of nutrients grown in the fields available to livestock. Essentially this means the exclusion of air from the ensiling mass. In addition, the structure should be so designed and located that it provides labour-saving storage that fits into a totally efficient handling system. The type of silo that is most economical depends on the amount of forage required by the farm. Each type of silo has advantages and disadvantages, and good management of each type is different (Table 1).

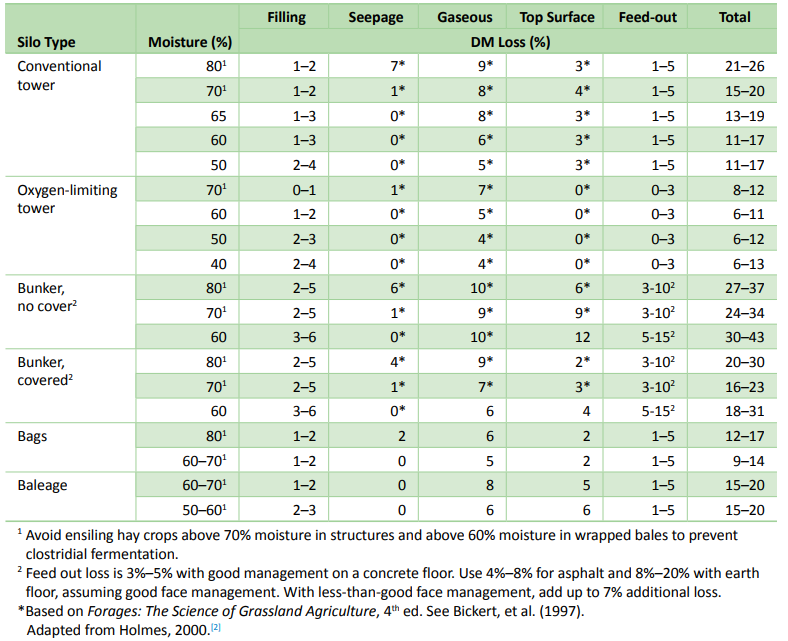

Table 1. Estimate of silage losses during filling, storage and feed out

A comparison of the suitability of different types of silos should include not only the initial capital cost, but also the yearly operating costs for the entire feeding system.

Any comparison of capital costs of silos must be based on equivalent storage capacity. Unfortunately, there is no uniformly accepted standard by which capacities are stated. One common measure is volume of usable storage space. However, a major disadvantage with this type of measure is that it does not take into consideration the compaction effect on silage due to height. This puts higher, larger diameter tower silos at a disadvantage. Another measure is the tonnes of silage the silo will hold. This, of course, is subject to wide variations in moisture content, fineness of chop, species of plant, method of distribution and packing, number of times the silo is refilled, etc.

One method of stating silo capacity for whole-plant silages, which eliminated some of the variation (particularly due to moisture content) is in terms of dry matter capacity. Within certain limits, it has been observed that a particular size of silo will hold a fairly constant amount of dry matter, regardless of the moisture content. Since the basis of ration formulation is dry matter, this method of stating silo capacities seems to be both practical and appropriate.

The fixed cost of owning a storage structure should include a value for such items as depreciation, interest, repairs, taxes and insurance. Variable or operating costs should include a value for the cost of labour and equipment operation.

The most suitable type of storage structure for a particular farm situation will vary with the type of livestock, the feeding program, the size of the operation and the types of feed.

The amount of snow and ice expected during a winter season should also be taken into consideration in selecting the type of silo. The more open a storage structure, the more adverse weather conditions affect the smooth, efficient operation of the silage handling system. In other words, farmers must recognize the normal winter-time climatic conditions where they live and select a silo and feeding system accordingly.

Tower Silos

In the past, vertical or tower silos have been constructed of many different materials. Today, nearly all are built of either concrete or steel. Tower silos may be further divided into two types: (a) open to the atmosphere on top, (i.e., open-top), or (b) sealed to control the internal atmosphere (i.e., oxygen-limiting).

Open-Top Silos

Nearly all open-top silos today are made of concrete, either cast-in-place (poured) or pre-cast stave. Basically, all open-top silos use some type of top unloader.

Oxygen-Limiting Silos

Most oxygen-limiting silos are constructed of steel or concrete. Of the steel units, the most popular is made of bolted panels of glass-fused-to-steel. As well, there are units available that consist of galvanized steel with some type of interior lining or coating to protect the steel from the corroding effects of silage acids. Oxygen-limiting silos are also constructed of concrete. Until the early 1980s, these were all cast-in-place units; since then several companies have started to market oxygen-limiting silos made with precast concrete staves together with some type of interior lining.

Nearly all oxygen-limiting silos are equipped with some type of bottom unloader; one silo construction company uses a top unloader with bottom delivery in its forage units.

Dry matter losses in well-managed tower silos are low, ranging from 5%–10%. Tower silos require no packing or covering, and therefore involve less labour at filling. Applying additives is simple. Tower silos unload in any weather and require less space. When all factors are considered, tower silos appear well-suited for farms using up to 150 tonnes (165 tons) of dry matter of a type of forage annually. Once this size is exceeded, the disadvantages of tower silos quickly outweigh the advantages.

The disadvantages of tower silos include potential safety issues with silo gas and the height of the structure, bottlenecks in the production process created by slow filling and the need to refill, and the incompatibility of slow unloading with total mixed ration (TMR) feeding.

Tower silos taller than 21.3 m (70 ft) restrict the moisture content of the forage stored. Excessive leaching forces owners of 24.4–30.5-m (80–100-ft) silos to harvest corn silage at more than the desired 35% dry matter, thereby compromising feed quality. Low-moisture corn silage has lower starch and fibre digestibility. Fibre digestibility has been found to decrease by over 10% as moisture decreases from 70%–58%. Kernels that are too dry will become hard and can pass through the cow undigested. The use of a processor or finer chopping can help compensate to some extent.

Use of a distributor will ensure adequate packing along tower silo walls and will help limit air movement into the silage from walls and doors. The filling rate should be very rapid for good packing. This will reduce air trapped in silage and minimize air traveling through silage. Temporary covers can be used if there are long periods of time between fillings, but beware of silo gases.

Bunker Silos

Bunker silos enable farms to handle large quantities of forage more efficiently. Silo height and width should be carefully planned to allow removal of a minimum of 15 cm (6 in.) of silage each day. A thicker slice will make the bunker easier to manage during the summer.

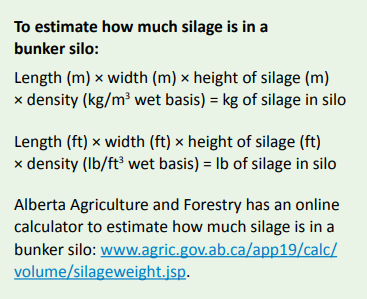

Dry matter losses in a well-managed bunker silo typically range from 10%–15%. Compaction studies have shown that the minimum height of a bunker silo should be 1.8–2.4 m (6–8 ft) to achieve the proper level of compaction. Width should be equal to or less than five times the height in order to maximize volume and minimize exposure to air at the bunker face.

The appropriate size for a bunker silo will depend on the amount of forage to be stored and the anticipated feed out rate. Dimensions become a function of size and management objectives. The recommended length for convenient packing is 45.7 m (150 ft) or less, and since two bunkers, emptied in alternate years, works best, two side-by-side bunkers of 27.4 m (90 ft) each could be sized width-wise to allow for 15 cm (6 in.) removal for year-round storage. Some producers ask about opening both ends of a bunker, but since the floor must slope away from the face, working from alternate ends is not practical.

The minimum recommended width is twice the width of the packing tractor or about 5.5–6.1 m (18–20 ft). Wider bunkers are appropriate if more capacity is needed, but since a 1-to-4 sloped crown is desirable to drain off rainwater, wide bunkers become very high in the centre. Wide bunkers also require additional walking to apply plastic and tires.

Sidewalls should be 2.4–3.1 m (8–10 ft) high. Most loaders can reach about 4.3 m (14 ft). This will be the height of silage in the centre of a 9-m (30-ft) wide bunker with a 1:4 sloped crown, and a 3.1-m (10-ft) sidewall. For bigger bunks, higher walls cost more per tonne of feed stored than additional floor area.

Bunker walls provide greater safety than unwalled piles for packing. Sidewalls also reduce the size of the face and the labour needed to pack and cover the silo. Instead of a single wall between bunkers, the more common design is for two interior walls, 1.2–1.5 m (4–5 ft) apart. Since cross-bracing increases the strength of this design, less concrete and steel is used in each of the walls and total cost is only slightly higher than a properly engineered single wall. The space between the walls is tile drained to the back of the silo and filled to 0.6–0.9 m (2–3 ft) of the top with gravel. When the silo is filled and crowned to the top of the wall, the space provides a safe working area for applying plastic and facilitates drainage of rainwater outside the silo. When the plastic is removed, the wall space has room for storing tires. Steps formed into the front panel of the double wall improve access to this area.

Bunker floors should slope 1% toward the opening for proper drainage. Asphalt has been gaining acceptance as a flooring material for bunker silos. Asphalt handles acids and freezing better than concrete. Place asphalt over a well-packed base. Use fabric under the base for stability. Construct a concrete curb around the edge of the apron to prevent damage from traffic entering and exiting the pad. On very hot days, tractor operators must take care not to spin tires, as the asphalt becomes softer in extreme heat.

Filling and Packing

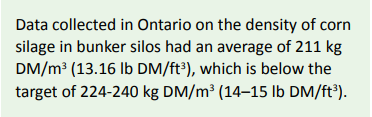

The target density in a bunker silo is 224–240 g dry matter/L (14–15 lb DM/ft3). Moisture content of the ensiled material should be no less than 60% and no more than 72% to allow adequate compaction and provide good fermentation. Filling should be done as fast as possible to maintain quality and stability of the silage during feed out.

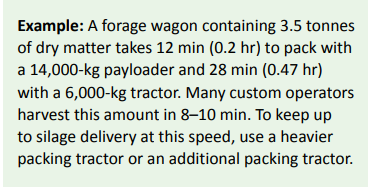

The time required for proper packing is determined by the weight of the packing tractor. Multiply the weight of the packing tractor (in kilograms) by the time spent packing the silage (in hours). Then divide the result by the tonnes of silage dry matter stored. A total of 800 hour-kilograms per tonne (1,600 hour-pounds per ton) is required to achieve proper packing. If the packing tractor isn’t heavy enough, consider adding weights to the tractor or tires, bringing in a second tractor or slowing down the harvest speed.

Bunker silos should be filled from back to front, in a wedge shape with a slope of 1:4, and by packing layers no more than 15 cm (6 in.) thick at a time. This method is known as a “progressive wedge.” Research has shown that the progressive wedge method improves preservation of digestible carbohydrates and increased stability at feed-out, apparently because of reduced exposed surface area when compared with the full-length method. It also permitted easier packing than the full-height method.

Covering

Research data from K.K. Bolsen and his Kansas State University team have shown that silage will lose an average of 30% or more of its dry matter when stored in an uncovered bunker silo.

The best option is to use an oxygen barrier plastic film specifically designed for covering silages. The use of 6- or 8-mil (1 mil = 1/1,000 in. or 0.0254 mm) plastic film is an alternative. In concrete bunkers, plastic should be used on the side walls and folded over the pile when the bunk is full to help prevent precipitation from running down the inside walls of the bunker. Drainage conduit is one option to use along the concrete edge to protect the side plastic from tearing while it is hanging over the side wall during filling. Weigh down the entire silage surface with tires, pea-gravel filled bags or other suitable materials. Research results show that a greater tire density increases silage preservation. For optimal results, place tires close enough to touch each other. It’s critical to seal the bunker properly as soon as possible after filling is finished. Do not follow any advice that suggests that the silage be left to settle after tractor packing is complete or wait to cover the pile until the next day. Greater losses occur the longer the pile is exposed to the oxygen in air.

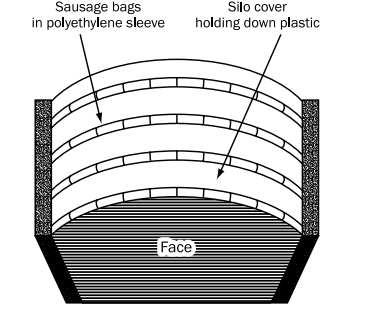

Sausage-bags are an alternative to tires. Instead of tires, sausage-bags filled with sand or gravel anchor the cover in place. The advantages of this system are the added protection, improved sealing, flexibility and ease of installation and storage of the sandbags. A polyethylene sleeve holds together several of the sausage-bags across the width of a silo. This product reduces the chance of air infiltration between the sausage bags. Figure 1 shows sausage bag placement. Use the sausage bags directly on the silo plastic, to reduce the cost and replace the use of tires. This is a good solution if birds or animals tear the plastic seal.

Figure 1. Sausage-bag placement

Feed Out

Feed out management is as important as filling. Losses can be large when the bunker is opened, and the face is exposed to oxygen. Take precautions to minimize oxygen penetration. Shaving or chipping the face will help achieve this goal. Keep the face as clean as possible. Removing the required amount of feed will reduce heating and keep dry matter losses to a minimum.

Bag Silos

Bag silos are frequently used as temporary silage storage when farms are expanding, or when they have higher forage yields than anticipated (Figure 2). If the integrity of the bag is maintained, dry matter losses are low and feed quality is excellent. For longer-term use as a permanent system, bags have a number of disadvantages. Unless they are placed on a well-drained, weed-free base, rodent damage is a constant threat. Hail and birds can also be a problem, and fighting the mud adds to labour costs. Bags require a large storage area. When the cost of preparing a large well-drained pad for the bags is included, the system becomes costly for long-term use.

Figure 2. Bag silo