Weather conditions and agronomic practices affect the amount of nitrates in plant material, which set the stage for the production of nitrogen dioxide (NO2) in the silo. For example, a dry period during the growing season followed by abundant rainfall will encourage a corn crop to take up high levels of dissolved nitrates. If the corn is harvested before the nitrates can be converted to proteins, nitrogen dioxide is produced.

Silo gas is produced almost immediately after filling a silo. The greatest risk is the first 12–60 hours after filling the silo, and then risk declines for approximately 4–6 weeks when silage fermentation is complete. Silo gas has a bleach-like odour and may be visible as a reddish-brown haze. However, it is not always visible.

Nitrogen dioxide is heavier than air, therefore it tends to be located just above the silage surface and on the ground around the silo. It may flow down silo chutes and into feed rooms. Tower silos are a greater risk because the silo gas is contained at the silage surface level, and operators often enter the silo after filling to level silage and set up the unloader.

When inhaled, nitrogen dioxide mixes with body moisture to form nitric acid, which causes severe burning of the lungs and the rest of the respiratory system. Pulmonary edema results. Victims often collapse. Other people attempting a rescue can also be overcome. People exposed to silo gas should get immediate medical attention.

To reduce the risk of injury or death from silo gases:

• Post a “Danger, Deadly Gases” warning sign in a visible location near the silo.

• Do not allow children or visitors near the silo for 3 weeks after filling.

• Provide sufficient feed room ventilation to exhaust any silo gas that might have spilled down from the silo.

• Check with your local fire department to see if pressure-demand remote breathing apparatus is part of their emergency equipment. Self-contained breathing apparatus (i.e., scuba) equipment is not suitable because of the air tank. It is sometimes too big for climbing the silo chute or the outside ladder-cage or too small to contain enough reserve air to rescue someone

• During filling, adjust the distributor as needed to level the silage. Do not level the material by hand.

• If it is necessary to enter the silo when filling is complete, do so immediately following the last load, on the same day. Remember to leave the blower running while inside.

Oxygen-limiting silos are a special case and should never be entered. If it becomes absolutely necessary to enter such a silo, it is essential that an external air supply be worn, and back-up emergency safety measures are in place. Consult Publication I33 Alert: Atmospheric Hazards Associated with Oxygen-Limited Structures (Silos) on Farms, by the Ontario Ministry of Labour, Training and Skills Development for suggested precautions.

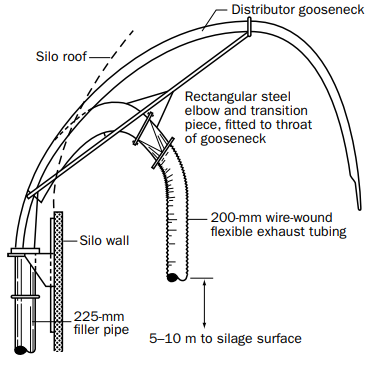

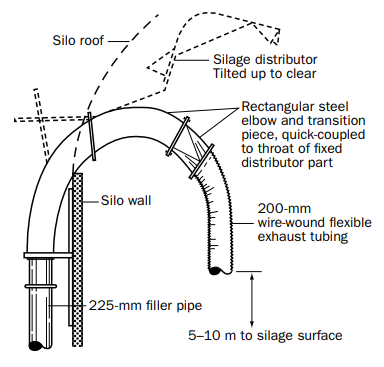

A top unloader can ventilate a silo effectively. However, if it becomes necessary to service a defective unloader, assume that gases are present. To expel gases before entering, run the forage blower with the chute doors closed and the roof vent open. If the head space is greater than 5 m (15 ft), attach a tube adapter to the blower pipe (Figure 1 and Figure 2). For a 7.2-m (24-ft) diameter silo with 5–10 m (15–30 ft) of head space, let the blower run for 30 minutes. For larger diameter silos or silos with a deeper head space, increase the ventilation time. Leave the forage blower running while in the silo.

If someone collapses inside a silo, begin ventilating with the forage blower immediately, as explained above, and contact your local fire department. A fresh air supply is critical for both the victim and rescuers. Never attempt to rescue someone yourself. This has been attempted many times and, without the proper equipment and training, has resulted in many incidents of multiple fatalities.

Figure 1. Suggested ventilation adapter for rotary distributors

Figure 2. Suggested ventilation for fin-type distributors

For more information on preventing injury or death from silo gas, refer to Silo Safety – Workplace Safety and Prevention Services, published by the Workplace Safety and Prevention Services.

Farmers with concerns about silo gas should contact the Workplace Safety and Prevention Services (formerly the Ontario Farm Safety Association) at 1-877-494-9777.