Baleage does not reach as low a pH as chopped haylage (and other types of silage). This means that greater emphasis must be put on good silage-making processes, especially the exclusion of oxygen. The length of storage time and how long the bales are exposed to oxygen before feed-out must be adjusted to weather conditions. In general, successful use of baleage will involve:

- baling a good-quality forage within 40%–60% moisture content in a very compact, even bale

- avoiding contamination by manure use or from soil-borne bacteria splashed up with rains or by raking

- wrapping the bales quickly, excluding the oxygen as soon as possible

- monitoring bales to maintain a continuous seal

- sizing the storage structure to allow efficient, quick feed out

- using good-quality plastic to produce a sealed environment.

Weather conditions are the prime reason that most people try a baleage system. The quality of the material produced, the use of existing equipment, and the ability to schedule harvesting operations to reduce the weather risk have increased the popularity of the system. It offers flexibility and the ability to store forage quickly if required.

Moisture Content

The moisture content of baleage at storage is one of the more important factors affecting quality. Baleage can be stored at moisture levels ranging from 40%–60%. At either end of the range, the risk of storage problems increases. Therefore, harvest should be geared to wilt material to an average of 50% moisture.

Many farmers prefer to harvest baleage on the dry side, which may be as low as 30% moisture. This exact moisture is difficult to establish at times because moisture determination on the farm is sometimes more qualitative than absolute. Drier forage makes handling bales easier, especially when loader equipment is small. The main problem is to be able to exclude the oxygen. Dry baleage contains more oxygen that must be used up in fermentation. It is extremely important to have tight bales made with a variable chamber baler when moisture levels approach 40%. It is difficult to make tight bales with mature forage because the coarse material won’t pack but it is safer to wilt vegetative alfalfa and grass to drier moisture levels. If the material is not well packed, more heat is produced from prolonged respiration. Heat damage may increase dry matter losses and bind protein, lowering the feed quality.

Extended wilting of the forage increases the risk of harvest losses. If the weather forecast is predicting rain, consider making baleage on the wet side to reduce weather losses. Baleage should be stored without rain damage. Moisture levels from 45%–55% offer the best storage for crops harvested for baleage. The moisture in the baleage should come mostly from the plant. Surface moisture from dew or rain does not provide sufficient moisture for fermentation. Baleage from forage originally intended for hay that had been rained upon or that was just too tough to dry bale often will not store well. Baleage will salvage this type of forage, but the product may lack the high quality expected.

Bales with higher moisture content are more likely to freeze or have more effluent that collects at the bottom of the silage bags. Problems with frozen large bales have been reported. These problems are more apt to occur as moisture levels increase above 50% and during extremely cold winters.

Storage Type

Baleage may be stored in bags, tubes or stacks. The oxygen present within any of these “containers” is not sufficient to cause excess respiration. If the oxygen can be kept out successfully throughout the storage time, good quality baleage can be made by any of these methods.

The trend in storage systems is toward using stretch wrap on individual bales or continuous line wrappers. Polyethylene tubes are still used but many farmers are using tubes of stretch plastic. Systems that minimize oxygen re-entry at feeding will reduce baleage deterioration.

The major suppliers of plastic wrap will guarantee plastic for up to 1 year. Properties of plastic include ultraviolet light inhibitors, stretch, puncture resistance and stickiness. Cheaper plastic often is of reduced quality. Most manufacturers recommend at least 4 layers of plastic with up to 6 layers for storage up to a year.

Individual Bales

Wrapping big bales with “stretch” plastic has proven to be an effective method of storage. This plastic film is basically a low-density polyethylene with a tacky additive to help it create a tight seal.

Individual wrapping is generally performed by machinery that rotates the bale on a turntable. The farmer starts the wrapping procedure by tucking the end of the plastic film under the twine, and when wrapping is complete, cuts the wrapped bale free. Wrapping machines are available to handle round or square bales of various sizes. Some equipment will handle both types of bales, however they are more costly.

Best results are expected when firm and intact bales are wrapped as tightly as possible (Figure 1). It is recommended that bales be wrapped with at least 4 layers of film for short storage and at least 6 layers of film for storage until the following spring to early summer.

Figure 1. Individually wrapped round bales

When handling individually wrapped bales, a grapple loader attachment is ideal (Figure 2). The use of a spear will break the seal and spoil the bale if not immediately fed or patched with a good quality silage tape. If stacking individually wrapped round bales, it is best to place bales two high on the flat end where there is more plastic.

Figure 2. A grapple minimizes punctures in the plastic wrap

The biggest advantage offered by individually stored baleage systems is the potential to minimize spoilage. Losses for well-wrapped quality baleage stored at the proper moisture content (60%) have been estimated at 5% of dry matter. For tight, well-wrapped bales, a hole in the plastic will mean only localized mould and spoilage rather than the widespread spoilage that develops when loose-fitting plastic covers are punctured. Another advantage to individually wrapped bales over multi-bale systems is the ability to market off-farm as it is very difficult to move a multi-bale unit (in-line or stack).

The latest major innovation in individually wrapped bales is the combination baler-wrapper, which wraps each bale as it comes out of the baler. This minimizes the amount of time the baleage is exposed to air before wrapping to maximize forage quality.

An alternative to using stretch film is the manual placement of bales into individual bags. If dealing with many bales, the bagging will work best with three people. Check all bags for holes immediately after bagging and then periodically afterwards. Patching can be effective if done with minimal delay. Haylage bags come in various sizes and thicknesses. The lighter bags are 4-mil polyethylene (1 mil = 1/1,000 in., or 0.0254 mm) and have a 1-year life expectancy, while 5- and 5.5-mil bags will often provide 2 seasons of use if the farmer is willing to patch any holes before reusing.

In-Line Systems

Multi-bale in-line systems were developed to decrease the cost, labour and time required wrapping or bagging individual bales. It is estimated that in-line systems use up to 40% less plastic over individual wrapping and will therefore be lower cost. There are in-line systems that can be used to store both round and square bales as baleage.

In Ontario, wrappers are the most common in-line system. These use the same stretch film as individually wrapped bales (Figure 3). In-line systems that use stretch film involve the placement of a bale onto the drum of the machine, which is then wrapped with the film. The greatest advantage to this system over a flex tube is that the length of each line of bales is variable and can be adjusted to fit individual operation feed out times and yard space.

Figure 3. An in-line wrapper

Flex tubes are another in-line storage option. These tubes are tied off at the end to keep air from getting into the line of bales. Some models are loaded one bale at a time (like the in-line wrappers), while others require the line of bales to be set up first so the filling machine can pull the tube over the bales. There are different machines of this style, which work with either loose-fitting bags or tight flex (stretch) tubes. With a tighter fitting flex tube, both plastic cost and potential for mass spoilage are reduced.

Stacks

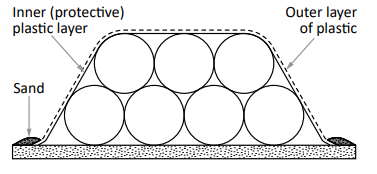

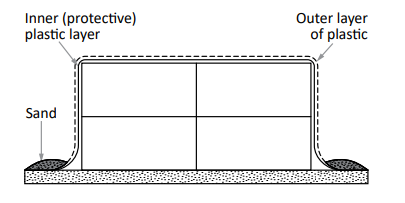

Covering and sealing stacks of baleage bales with a double layer of 6-mil polyethylene can preserve them. This method works well for both round and big square bales. As shown in Figure 4, the outer layer provides the seal, while the inner layer protects it from stem punctures, especially where twine or rope tie-downs are placed. Sand is used to seal the edges of the outer layer, and substantial tie-downs are required to minimize wind buffeting.

Do not use construction-grade polyethylene since a big percentage of it is made from a variety of reclaimed plastics, resulting in an inferior product with variable thickness. Although silage films cost more, they are made from pure resins and exhibit vastly superior physical properties (stretch, puncture-resistance, and fatigue). In quality silage films, a uniform thickness is maintained.

The amount of air initially trapped under the plastic is not critical since the respiration process quickly uses up oxygen. However, any subsequent hole in the plastic will allow oxygen to enter freely and cause extensive spoilage. As with the other options, take steps to minimize rodent problems and check the cover periodically.

Figure 4. Round bale stack face (stacks should be 3-5 bales long)

Some farmers have chosen to place loose haylage in the voids between bales and between the bales and the plastic cover. The benefit gained here is that the free movement of air through the stack may be lessened if the stack’s seal is broken.

Once a stack is opened deterioration of the baleage commences and continues at a rate that varies with air temperature. Eventually, mould becomes visible on the face of the bales and gradually will penetrate the bales. Plan your stack size so that once opened, it will be entirely fed out: within 1 week in summer, within 2 weeks in spring and fall and within 4 weeks in winter.

If stacks are kept small (21–35 round bales or 20–40 square bales), placing the plastic will be easier, minimizing problems with ice and snow during winter feed out.

When stacking round bales (Figure 4), do not build stacks more than 2 bales high due to the tendency of these heavy bales to squat and become somewhat unstable. In a high stack there is potential for the top bales to shift in any direction, possibly breaking the polyethylene seal.

The stacking method shown in Figure 5 works best with square bales as more hay can be fit under the same sheet of plastic. Due to their flat edges, square bales have fewer tendencies to shift and settle and are therefore less likely to break the seal of the stack.

Figure 5. Big square bale stack face (stacks should be 5-10 bales long)

For any baleage system, air holes will cause extensive spoilage and, if undetected, may render the bale(s) a complete waste. Avoid rodent damage by eliminating long grass around the storage site. Keep in mind that even a pinhole allows enough air exchange for spoilage to occur.

Storage Time and Location

The longer the time in storage, the higher the risk of silage deterioration. Baleage that is fed out in the fall or winter has generally not been a problem. Cool temperatures work in favour of preservation, keeping microbial activity limited. When temperatures start to increase in late March, moulds that were in the baleage at low levels may develop into a problem. If fermentation is not complete, spoilage will be more severe.

Farmers have observed that fall silage put up in late summer or early fall does not change colour or have any acid smell. This indicates fermentation either did not take place or was very limited. Cooler temperatures and lower numbers of bacteria may be responsible. It is possible fermentation will start again as temperatures warm up in the spring, but this assumes oxygen has not penetrated over winter. This silage is best fed out during the fall and winter to avoid spoilage.

Plastic will attract rodents and just about any other animal capable of putting holes in plastic. The storage area should be clean of vegetation as much as possible to prevent cover for rodent movement and be protected from other animals.

Moulds

A farmer considering baleage must accept that moulds are a fact of life. Even under ideal circumstances, a small percentage of bales will exhibit some white mould. A bale that has been exposed to oxygen for an extended period will exhibit severe black mould throughout much of the bale.

Secondary mould growth may take place as baleage is removed from the tubes. If the baleage has not properly fermented or contains high populations of yeast and/or mould, oxygen entering the tubes will quickly deteriorate the baleage. The implications of oxygen breakdown are important with round bale baleage systems using tubes because oxygen may enter the tube as soon as it is opened. Slow feed out through the spring and summer may cause problems. Bales should be fed within 1 week in the summer, 2 weeks in the fall and early spring, and 4 weeks during the winter after opening the tube or storage structure.

Livestock will usually still consume mouldy material unless there are too many spores, which cause lung irritations. People can also be affected by these spores, which can lodge within the lungs. The acids produced by fermentation are volatile and thus may migrate from the bale if air enters or may also be leached with moisture migration resulting in areas where moulds may establish.

A white mould or yeast is very common. It produces a large spore that will not irritate lung tissue or cause feed refusal. Other moulds that may occur are aspergillus, a grey/blue mould, which may aggravate allergies or cause abortions in cattle, and fusarium, a red or pink mould that can produce deoxynivalenol (DON), T2 and other toxins that cause feed refusal and vomiting and have estrogen-like effects in livestock. The spores produced by the moulds usually cause the most damage. White mould is not a problem, but the other-coloured moulds should be regarded with care.

Temperature affects how quickly moulds develop. Fusarium grows at 4.5˚C–15.5˚C, but aspergillus and penicillin grow at 18˚C–35˚C. This silage would be just warm to the touch. As outside temperatures rise, the temperature of the material will rise into these ranges. The acids produced by fermentation inhibit mould growth, which is why good fermentation practices are so important when making silage and baleage.

Manure should not be applied to the forage stand before harvest as this introduces undesirable bacteria to the forage that may stimulate mould growth. Raking seems to make the problem worse. Rain during wilting may splash soil-borne bacteria and mould onto the forage. Manure contamination will spoil a pocket of the bale but not necessarily the entire bale unless other problems exist.