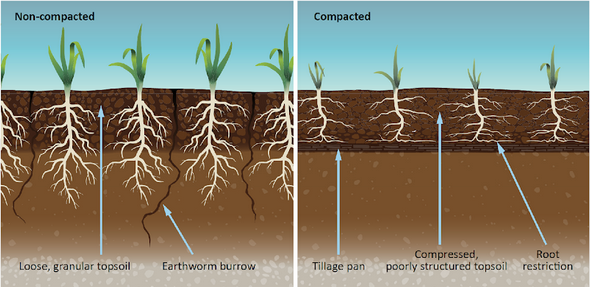

Soils are made up of minerals (sand, silt and clay particles), organic matter and pore spaces that contain water and air. Compaction in its purest sense can be defined as “an applied pressure/force exerted on a landscape that reduces pore space within the soil matrix” (Figure 1). Crops grown in compacted soils often have a restricted root system. This leads to poor nutrient uptake, stunted growth, a general lack of vigour and reduced yields. Compaction-affected plants are also more susceptible to disease and insect pressure.

The effects of soil compaction often go unnoticed in forage fields, but compaction can impact yield. Research has shown that compaction can cause between 6% and 74% yield loss in perennial forage stands.[1] Heavy equipment, high tire pressures and multiple passes create more severe compaction. One study reported grass yield losses increase from 5% to 15% as the pressure exerted by the tractor on the ground rose from 10 to 30 psi. The study also showed a 33% reduction in yield when comparing a 3-pass system to a single pass.[2]

Yield impacts from compaction are primarily the result of decreased pore space within and between soil aggregates or clods. This reduces water infiltration and drainage, aeration, root growth, and nutrient availability and uptake. Low aeration can decrease nitrogen availability because of denitrification, and a low-oxygen environment leads to reduced root respiration that can restrict potassium uptake. Phosphorus uptake can also be reduced by up to 40% if root growth is significantly impeded.[3]

The risk of causing soil compaction can be reduced by waiting until soils are dry enough to carry equipment. No-till and conservation tillage cropping systems maintain the soil’s ability to carry equipment because the structure stays intact. Heavier equipment has a greater risk of causing compaction, so choosing the smallest tractor that can safely do a job will reduce the load on the soil. Adjustments can be made to agricultural equipment to further reduce compaction during field work.

Tire selection can help reduce soil compaction. Agricultural field tires exert less pressure on the soil than road tires. Increasing the number of axles and tires under equipment and wagons disperses the weight over a greater surface area, much like snowshoes distribute a person’s weight across the snow. Inflation/deflation systems can be installed on tractors with lines to implements; when paired with appropriate tires, these systems can quickly pay for themselves in reduced soil compaction through higher forage yields.

The front tires on front end loaders are not big enough to support the weight of a bale. Where possible, plan traffic through the field and use bale loaders or gatherers.

It is not always possible to fix soil compaction after the fact. Deep compaction (caused by equipment) is harder to fix. Shallow compaction (caused by equipment or livestock) will over time fix itself because it occurs where roots grow, microbes live, and frost enters and leaves the soil. These processes help break up mild-to-moderate shallow compaction.

References

1. Jorajuria, D., and L. Draghi. 1997. The Distribution of Soil Compaction With Depth and the Response of a Perennial Forage Crop. Journal of Agricultural Engineering Research. 66(4):261-265.

2. Rasmussen, K.J., and E. Moller. 1981. Regrowth after pre-wilting of grassland crops. II. Soil compaction in connection with harvest and transport. Tidskr. Planteavl. 85: 59-71 (In Danish, with English summary).

3. Chamen, W.C.T., A.P. Moxey, W. Towers, B. Balana and P.D. Hallet. 2015. Mitigating Arable Soil Compaction: A Review and Analysis of Available Cost and Benefit Data. Soil & Tillage Research. 146: 10-25.