The key to good baleage is the exclusion of oxygen quickly and completely. Start with a very compact bale to reduce air pockets in the bale. Tight bales are made by reducing the tractor speed and picking up hay directly from the windrow that has not been raked. If raking is required to allow faster drying, try to maintain a wide windrow. Hard-core balers are preferred over soft-core balers. Both roller and belt type balers can be used. Bale density should be around 192 g/L (12 lb/ft3). This equates to a weight of 544 kg (1,200 lb) in a typical 1.2 m × 1.2 m (4 ft × 4 ft) round bale at 50% moisture. Plastic twine is recommended for tying bales, as the oil-based preservative in sisal twine will degrade plastic wrap.

Bales should be moved to the storage area immediately. If left too long, they will begin to heat and lose feed value. The sun may evaporate moisture on the outside of the bale, making stems brittle. Bales, especially higher-moisture bales, lose shape, making them more difficult to wrap. Storage should be complete 6 hours after baling and not later than 12 hours.

Advantages of baleage:

- uses existing haymaking equipment

- lower harvest losses than dry hay

- less weather dependent than dry hay systems

- higher-quality feed (due to earlier harvest window)

Disadvantages of baleage:

- heavier bales may require larger handling equipment

- increase in annual costs

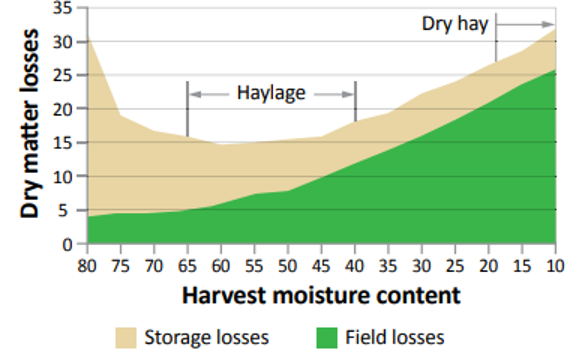

- potentially higher storage losses

Dry matter losses in the field, largely the result of shattering and loss of protein-rich leaves, are cut substantially by harvesting a wetter material. For example, harvesting baleage at 55% moisture as opposed to dry hay at 18% can cut field and storage losses approximately in half (Figure 1).

Figure 1. Field and storage losses.

Use only top-quality forage for baleage. Poor quality, rain-damaged material, or a forage crop that is mature and lacks the sugars necessary for good fermentation will not produce quality feed and will have a reduced storage life.

Wilt the crop to 50%–60% moisture. At this moisture level, fermentation is more favourable in terms of sugar content than in wetter material, and seepage losses are minimized. The amount of forage mowed must be coordinated closely with drying conditions, baling, and covering. If the crop gets much drier than 40% moisture, let it dry for hay. Ensiling material with too little moisture increases the risk of heating due to increased oxygen penetration, which will lead to mould growth and a marked depression in the protein digestibility.

Proper machinery for making and transporting heavier, high-moisture bales is necessary. Do not attempt to work with very large bales. A 1.2 m × 1.2 m (4 ft × 4 ft) (diameter × length) bale at 55% moisture will weigh 544 kg (1,200 lb) whereas a 1.2 m × 1.5 m (4 ft × 5 ft) bale at 55% moisture content will weigh 680 kg (1,500 lb).

It is important to move the bales to storage and enclose them in plastic as soon as possible after baling. Regardless of whether the baleage is stored individually, in tubes or in stacks, sealing all air out is critical. During the respiration stage of the ensiling process, the oxygen that is trapped in storage is rapidly consumed by aerobic bacteria. Anaerobic bacteria, which survive in the absence of oxygen, begin to grow and multiply in the fermentation stage and convert the plant sugars into organic acids – mainly lactic and acetic.

With production of acids, the pH of silage is reduced from an original level of 7.0 to a final pH of 4.0-5.0, while baleage has a pH of 4.5–5.5. Fermentation ceases when bacteria growth is stopped by the accumulation of acids. The forage will then remain at a stable pH with no bacterial growth and can be preserved for a long time, providing there is no exposure to air.

Using silage additives to aid fermentation is generally unnecessary, however they may be beneficial in situations where forage material is drier than recommended, or the wilting conditions are cool and dry.