Fast drying is key to successful haymaking. In this part of the world, good haymaking periods without rain are frequently narrow. It is often a struggle between getting the hay dry enough to bale before the next rain or baling before the hay is quite dry enough and getting mouldy, dusty hay.

Conditioning and raking must be balanced against excessive leaf loss. While the weather is beyond a grower’s control, there are management decisions that can be made to increase the chance of making good quality dry hay.

Swath width is an easy adjustment that has a big impact on drying time. Spread the crop as wide as practical. Do not cut hay into a tight windrow. A wider swath will dry faster, because more area of the hay is exposed to sun and wind. Solar radiation cannot penetrate very deep into the swath. University of Wisconsin research indicates that a 3.6-m (12-ft) haybine laying a 2.7-m (9-ft) swath will reduce drying time by 35% versus a 1.8-m (6-ft) swath. Wind speed and humidity are the most influential weather factors affecting drying time.

A higher cutting height (7.5–10 cm (3–4 in.)) comes at the compromise of some yield loss but allows air to move underneath the swath and speeds drying. If the ground is wet and in contact with the windrow, the hay will absorb moisture.

Cutting hay in the morning, after the dew is off, maximizes daylight hours for drying and minimizes respiration losses. Research that suggests delaying cutting until late in the day to maximize sugar content is based on the dry environment of the western U.S. and does not typically apply to the high humidity conditions of the Great Lakes area.

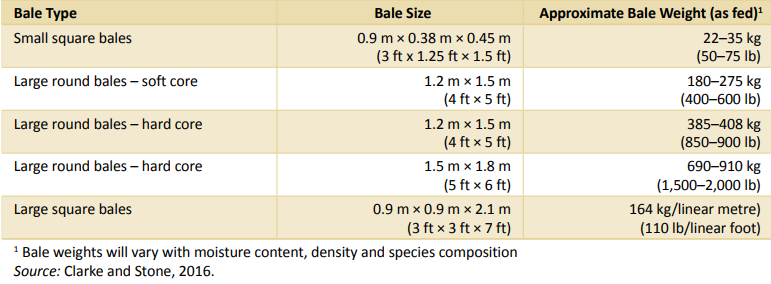

The reasons for using either round or square bale systems vary from farm to farm (Table 1). Existing baling and handling equipment, storage facilities, amount of hay made, and the availability of local custom operators are all factors to take into consideration.

Advantages of round bales:

• more widely available, less expensive baling and wrapping equipment

• variable diameter bales (hard core balers) can be made smaller to reduce weight

Advantages of large square bales:

• safer to handle than round bales

• higher stacking density (reduced storage space and cost)

Table 1. Approximate Bale Weights

Preservatives

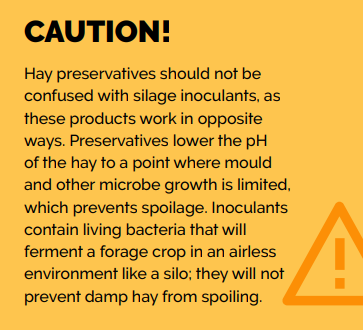

Hay preservatives are additives that contain acid, which enables dry hay to be baled at slightly wetter moisture content than ideal. The goal of using a preservative is to prevent mould growth and spoilage in “almost dry” hay.

Moulds greatly reduce the value of dry hay, particularly when targeting the high-quality horse hay or dairy hay markets. Moulds consume hay nutrients and cause dry matter losses, as well as producing toxins that are detrimental to animal health. Mouldy, dusty hay contains spores that can cause respiratory problems, particularly with horses. Mould growth can even result in hay fires from spontaneous combustion.

The most common acid in hay preservatives is propionic acid. Propionic acid is an organic acid that acts as a fungicide, inhibiting the growth of aerobic microorganisms that can cause heating and moulding. Other organic acids, such as acetic and citric acids are sometimes also included, but propionic acid is the most effective as a mould inhibitor. The propionic acid inhibits mould growth while the bales “sweat” and cure down to safe moisture levels by dissipation and evaporation.

There are three situations when propionic acid application to dry hay is most economical:

• used strategically to avoid rain damage on “almost dry” hay when the weather does not cooperate

• large dense bales that are difficult to dry to low enough moistures to avoid mould

• custom operators and producers baling large volumes that can pass the costs onto customers that demand mould- and dust-free hay

Propionic acid is sprayed onto hay as it enters the baler. Equipment includes a baler-mounted applicator with a pump, nozzles, and tank.

Read and follow label directions. Enough acid must be applied using the correct rate of active ingredient for various moisture levels for it to work properly. Different products have different concentrations of active ingredients. Using very dilute products provides greater coverage but requires more water to be applied on the hay that is already too wet.

Application at the correct and uniform rate is key. Uneven windrows or fields with wet spots will not have uniform moisture. Use a moisture tester to determine application rate, using the highest reading. If using the average reading, not enough acid will be applied on much of the hay to prevent spoilage. Spraying should be as uniform as possible to ensure good coverage.

Hay can still heat and become mouldy and discoloured if inadequate acid is applied. Tightly stacked bales in a confined area do not allow the bales to “sweat” and cure. The acid can dissipate in 4–6 months, which may be before hay moisture is low enough if conditions are unfavourable. Extended periods of high humidity will extend the curing time. Do not store treated and untreated dry hay in direct contact with each other, as the moisture will migrate to the untreated hay.

The original propionic acid products were unbuffered, which meant they were highly corrosive, very volatile, and difficult to work with. Products now marketed are buffered to a pH of 5.8 to 6.0 with ammonium hydroxide. Buffered products are much less volatile and corrosive, making them much easier to use. Other ingredients sometimes included are surfactants and green colouring. Products differ in concentration of propionic acid, so purchase decisions should be based on the price per kg of active ingredient.

Hay treated with buffered propionic and other organic acid products is safe to feed to livestock. Propionic and acetic acids are organic acids that are produced by microbes in the rumen (and the cecum and colon of horses) and then used by the animal as part of the digestion process. Some horse owners are not comfortable feeding acid-treated hay and prefer not to purchase it. There may initially be some propionic odour in the hay until it has dissipated. Be sure to inform hay buyers that propionic acid has been applied.

Dryers

A properly managed hay drying system reduces field curing time, lessens the risk of losses due to rain, minimizes leaf loss and eliminates the danger of fire due to spontaneous combustion. In Ontario’s humid climate, a hay dryer is a valuable tool for consistently making high-quality hay.

The hay dryer is designed to dry tough or damp hay but not wet hay. Field dry the hay to an average moisture content of 25% before baling. Hay with a high grass content may be baled with a slightly higher moisture level. Bale the hay at normal baler tension and make slight adjustments, if necessary, for high moisture content. Remember that the bales will shrink slightly during the drying process.

The capital cost of the hay drying system varies, depending on the type and size of the system. Operating costs depend on hay moisture content and weather conditions during the drying period.