The stages of silage harvest prepare the crop for efficient fermentation in storage. Efficient fermentation preserves forage quality and minimizes dry matter losses and spoilage.

Wilting

Wide swath haylage to achieve “haylage-in-a-day” and improve forage quality is becoming a popular management practice. This is contrary to the more typical practice of using the mower-conditioner to place the swath in a narrow windrow for a day or two of wilting, and then chop directly. Wide swath haylage requires some innovation and significant changes in both equipment and management, but research indicates that improvements in forage quality can be quite impressive.

Leaf stomata are generally open during the day and closed at night (or on the bottom of a tight swath). A wide swath maximizes exposure to sunlight, which keeps the stomata open and maximizes exposure to solar radiation (heat and lower humidity). Contrary to some Western U.S. research, in conditions similar to Ontario with high humidity and warm nights, respiration losses during the night exceed the extra sugars expected by cutting late in the day.

Rapid wilting after cutting is critical to minimize respiration losses of sugars in high-quality haylage. This is especially true for higher yielding first-cuts. Plant respiration continues after cutting until about 60%–65% dry matter, when the cells die. Respiration converts stored carbohydrates (starch and sugar) to carbon dioxide, heat and moisture, and causes dry matter losses and increased fibre percent. Forage that is higher in the soluble carbohydrates will have greater digestible energy, but also can provide a more readily fermentable substrate to lactic acid bacteria, resulting in better haylage fermentation. The longer the wilting period in the field, the greater the respiration losses (less sugars), and the lower the forage quality.

Wider swaths dry faster, so adjusting the mower to leave as wide a swath as possible makes sense. Research by Tom Kilcer, Cornell University Extension, indicates that wide swath width (85% of cutter-bar width) and sunlight (cutting in the morning) are the keys to fast wilting for haylage high in digestible energy and improved fermentation. Freshly cut forage does not know it is dead yet. Carbohydrates gained from photosynthesis in a wide swath exposed to sunlight typically exceeded losses from respiration. The Cornell research indicates that wide swaths can significantly improve forage quality, consistency, and milk-per-ton of haylage. Milk per ton was improved by 136 kg (300 lb). As a bonus, haylage-in-a-day also reduces the risk of rain damage.

Most mower-conditioners have an easy swath width adjustment. Dr Ron Schuler (Extension Engineer, University of Wisconsin) reports that the average maximum swath width on the North American market is 61.4% of the cut width, with a range of 28%–87%. Self-propelled widths are usually narrower. Swath width percentage should be a consideration when purchasing a new mower; the wider the better.

Of course, wide swaths will likely require that the swaths be moved and narrowed for chopping. This is an obstacle preventing many from making wide swath haylage. Some are adopting the use of windrow mergers that use a pickup and belt (similar to an inverter, but wider) rather than rakes, in order to reduce the risk of rocks, clostridia and ash. A rock in the chopper is a problem to be avoided. Combining two or more windrows into one with a merger requires an extra field operation, but it increases chopper capacity and speed. Moving an “almost ready” swath with a merger also speeds wilting. A merger is cheaper and faster to run than a harvester.

There is some concern about driving on a wide swath. The Cornell research indicates that in a wide swath situation, driving on the cut swath with the tractor is not an issue that significantly affects drying. However, there may be some potential for soil contamination that adversely affects fermentation, particularly in wet field conditions. Tractor tires can be set as wide as possible.

Before purchasing wide swath haylage equipment, it is important to consider the compatibility of the:

• mower (or mower-conditioner) swath width

• merger pick-up width

• forage harvester pick-up width

Chopping

The size of chopped forage particles affects how well the crop packs in the silo, which influences fermentation efficiency. Large particles resist packing more than small ones, and this resistance increases the amount of air left in the silo. The extra air slows fermentation, which can increase shrink.

Particle size also affects how the silage feeds out. If the chop length is too short, the forage will pass through the ruminants’ digestive tracts too quickly and can cause health issues such as rumen acidosis. If the forage is not chopped fine enough, the coarse material will fill animals quickly, and dry matter intakes will decline. Particles chopped to an ideal size will stimulate chewing and saliva production, buffer against rumen acidosis and optimize dry matter intake.

Theoretical length of cut should be set at 10 mm (3/8 in.) for alfalfa haylage to provide 15%–20% of forage particles at greater than 37.5 mm (1 ½ in.) long. This short length aids packing, and in the case of tower silos makes for easier unloading.

Penn State Particle Separator

A Penn State Particle Separator (PSPS) can be used to measure the physical effectiveness factor, or particle length, of total mixed rations and forages (Figure 1). Unlike other established laboratory methods for assessing physically effective fibre, the PSPS is a fast and practical tool that can be used to estimate physically effective fibre in the ration on-farm.

Figure 1. Penn State Shaker Box used to measure particle size distribution in ruminant rations

The 2013 version of the PSPS has three sieves (19-mm, 8-mm and 4-mm openings with a bottom pan). The physically effective component of a ration is calculated as the amount of material retained on the three sieves, expressed as a percentage of the whole sample.

Technique:

1. Stack the four separator boxes. The sieve with the largest holes (19 mm) should be on top, followed by the sieve with medium-sized holes (8 mm), then the sieve with small holes (4 mm). The solid box is on the bottom of the stack.

2. Place about 1.5 L (6 cups) of forage or total mixed ration (TMR) in the top sieve.

3. Shaking must be done on a smooth surface. To shake, slide the stack of boxes away from, then towards the operator in a quick motion. The stack should slide about 17.5 cm (7 in.) away from the operator. There should be no vertical movement of the separator boxes. For best results, operators should aim for a rate of 1 shake/second.

4. Shake the stack five times. Turn the stack one-quarter turn (90˚).

5. Repeat step 4 seven times. This is a total of 40 shakes, or eight sets of five shakes.

6. Weigh the material in each box and record the weights.

7. Sum the weights of the materials in each box together.

8. To calculate the percent of material in each box, divide the weight of material in one box (step 6) by the total weight of material in the sample (step 7). Multiply by 100.

To estimate physically effective Neutral Detergent Fibre (peNDF), the proportion of feed on the top three sieves is multiplied by the NDF content of the feedstuff or ration. Caution must be taken when accounting for the 4 mm (bottom) screen, since this screen is meant to capture particles that are high in fibre, but other feed ingredients and by-products can also be trapped on this sieve. When a large amount of grain and supplement is trapped on this bottom sieve, which is often the case with finishing rations, the bottom screen should be discounted when calculating peNDF.

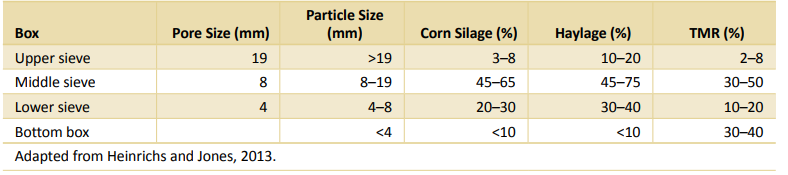

Table 1. Particle Size Recommendations for Lactating Dairy Cows

The role of effective fibre in maintaining rumen health and influencing milk composition has been well-established in the dairy industry, and the results of a PSPS can be interpreted to adjust the chop length of dairy rations (Table 1). Research is underway to expand the use of the PSPS to beef finishing rations.

More information about using a PSPS is available at extension.psu.edu/penn-state-particle-separator