Correctly timing how long to let the crop wilt when harvesting a forage crop will help ensure that it stores well. It either needs to have enough moisture to ferment correctly without seeping, or low enough moisture content to preserve as dry hay.

There are three types of moisture to consider when wilting a forage crop: stem moisture, dew moisture and air humidity. Stem moisture is the amount of water within the plant. Dew moisture is water outside the plant, whether it is from rain or condensation (dew). Air humidity affects how quickly the crop can dry. If the air is already holding a lot of water, it takes longer for the forage to dry down, even if the air temperature is hot.

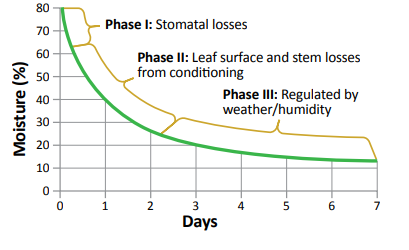

A standing forage crop is typically between 70% and 85% moisture. During the first phase of drying, the plants are losing moisture through open stomata in their leaves (Figure 1). Forage crops do not stop photosynthesis and cellular respiration when they are cut. These processes continue until the plant’s moisture level drops below 60%. Stomata will stay open and enable crop drying so long as the leaves are exposed to light. Most of the wilting for a silage/haylage crop occurs in this way. Part of why hay at the bottom of a windrow dries more slowly is because the stomata are closed in the dark bottom of the pile. This is one reason wide swaths reduce drying time.

In the second phase of drying, the stomata are closed (moisture content is less than 60%), and the crop is losing moisture from the stem rather than from inside the leaves. This wilting is slower than the first phase. Conditioning the crop can speed up this second phase by cracking the stem to allow more moisture out. Most of the dew moisture on the outside of the plant is lost during this second phase. Crops wilted for baleage will have some of their drying time in this phase.

The third drying phase is the slowest, as the remaining water (<30%) is held very tightly in the stems. However, it is critical for dry hay to get the moisture content below 18% for small square bales, and below 14% for large bales. Air humidity has a large effect on this drying phase, which makes it challenging in Ontario’s climate. Hay dryers can be used to speed up this phase, reducing the risk of the crop being rained on.

Figure 1. Hay drying curve.

Moisture Testing

The only way to know whether a crop is appropriately dry is to measure the moisture content. Using the results to guide the rest of the harvest process will protect yield and quality in storage. There are several methods available to measure the moisture content of a forage.

Be aware that samples have residual moisture that is not removed when dried with a Koster Tester or microwave but will be removed in laboratory ovens. The most accurate option is to send a sample by overnight delivery to a forage laboratory for oven drying. Results can be e-mailed immediately.

The Miner Institute has estimated that Koster Testers and microwaves underestimate moisture by about 3%. A 68% moisture sample reading is actually about 71% moisture. When using a Koster Tester or microwave, taking the time to carefully dry the sample is important. The finer the sample is chopped, the easier it will be to dry and the more accurate the result.

Microwave Oven Method

A microwave oven can be used to dry forage samples quickly. The main advantages to this method are the speed of drying and the availability of the equipment. Care must be taken not to burn the sample. The disadvantages of using a microwave to determine moisture content are that it can only dry one sample at a time, it takes time, and the smell tends to linger.

Technique:

1. Weigh the container and record the empty weight; OR tare the scales with the empty container on them.

2. Add 100 g (3.5 oz) (W1) of forage to the container.

3. Spread the weighed forage sample on a paper plate or place it in a paper bag and put it in the microwave oven.

4. Place a 250 mL (1 cup) glass three-quarters full of water in the microwave to prevent igniting the sample or damaging the microwave oven.

5. Heat at 80%–90% of maximum power for 4 minutes.

6. Remove the sample, mix it and weigh it.

7. Continue to reheat for 2-minute intervals, re-weighing each time. To prevent burning, use lower heat and 30-second time intervals as it approaches being dry. If the weight of the sample does not change after two or three drying intervals, it is 100% dry. This is the final dry weight (W2). A slightly charred sample should not affect accuracy of the moisture determination but if the sample burns the test should be repeated.

8. Calculate moisture content as follows: Moisture Content = (W1–W2) ÷ (W1) × 100

Koster Tester Method

The Koster Tester was specifically developed for drying grains and forages for moisture testing. Its main advantage is the ease of use; however, the drying time involved can result in a mismatch between the sample result and a cut crop wilting in the field.

Technique:

1. Weigh the drying basket of the tester and record the empty weight; OR tare the scales with the empty basket on them.

2. Add 100 g (3.5 oz) (W1) of forage to the drying basket.

3. Place the basket with forage sample on top of the heating unit and let it dry for 30 minutes.

4. Weight the sample and record the weight.

5. Dry the sample for an additional 10 minutes. Weigh the sample again and record the weight.

6. Repeat step 5 until the weight change is less than 2 g (0.07oz) repeatedly (W2).

7. Calculate moisture content as follows: Moisture Content = (W1–W2) ÷ (W1) × 100

Electronic Testers

Electronic moisture testers estimate percent moisture by measuring the resistance of electricity to move through a hay sample. The wetter the hay, the more electricity flows through. There are two basic types: in-baler sensors and hand-held probes.

In-baler moisture sensors enable the operator to monitor moisture on-the-go from the tractor seat. Sensors can be located in-chamber on square balers, and on the sidewalls of large round balers. In-baler sensors have the advantage of giving numerous, continuous readings. They are usually installed as a component of a hay preservative application system. Preservative application rates can then be adjusted either manually or automatically according to the moisture. In-baler moisture sensors with automatic applicators are commonly included on large square balers and are also available for large round and small square balers.

Hand-held probes are designed for measuring the moisture content of a bale. Accuracy is affected by bale density, whether it is grass or alfalfa, whether the water is stem moisture or dew moisture, and whether acid has been applied. Electronic moisture testers need to be calibrated to the conditions and well maintained. Beware that digital readings do not give you a false sense of accuracy. Moisture testers should be used to supplement personal experience.

Hand-held probes cannot accurately measure the moisture content of forage in a windrow. Ron Thaemert from the University of Idaho developed a windrow sampling tool that enables producers to compact a sample of cut hay so that a probe can measure the moisture content (Figure 14-2). Materials required to build a windrow sampling tool are as follows:

• 61 cm (2 ft) of 2 in. diameter ABS pipe

• 91 cm (3 ft) of 1 ¼ in. diameter PVC pipe

• two 1 ¼ in. PVC pipe caps

• 2 in. ABS female coupling

• 2 in. ABS cleanout adapter

• 2 in. ABS cleanout plug

• solvent cement

With solvent cement, attach the pipe caps on the 1 ¼ in. PVC pipe. This will be the plunger. Glue the cleanout adapter on one end of the 2 in. ABS pipe. Screw the ABS cleanout plug into the adapter. This is the collection tube and it will simulate a bale chamber.

To use the windrow sampling tool, turn a portion of a windrow over. By feel, select the dampest hay in the sample area and fill the collection tube. Place the capped end of the collection tube on the ground. Insert the plunger into the collection tube to compress the hay. Insert the moisture testing probe into the collection tube and record moisture readings at depths of 10 cm (4 in.), 20 cm (8 in.), 30 cm (12 in.) and 40 cm (16 in.). Use the highest of these readings as the sample moisture.

Moisture content varies within and along windrows, and across the field. A minimum of 20 windrow samples are recommended for every 180 tonnes (200 tons) of forage to give producers a clear indication of how dry the crop is.

Figure 2. An electronic bale moisture probe cannot measure the moisture content of loose hay. Using a windrow moisture sampler to compact the hay sample makes rapid moisture testing before baling possible.

Near Infrared Reflectance Spectroscopy (NIRS) Testers

NIR spectrometers shine infrared light, which is invisible to human eyes, at the forage sample and measure how much of the light bounces back. The bounce pattern is compared to a calibration for the type of forage in question, which provides an estimate of the amount of water in the sample. Handheld NIR spectrometers are capable of measuring moisture content very quickly and easily.