No-Till Systems

In no-till systems, tillage is not used to prepare a seedbed. Minimal soil loosening in a narrow band immediately ahead of the seed opener is performed by planter-mounted coulters and/or residue clearing devices. Successful no-till corn production is partially dependent on effective use of field management strategies which may include alternative production practices that compensate for what tillage provides in other systems. For successful no-till corn production, the following issues must be carefully addressed:

• soil drainage

• crop rotation

• residue management

• weed control

• disease/insect management

• fertilizer placement

• soil compaction

Soil Drainage

Soils experience slower spring drying rates in no-till systems due to the lack of soil loosening and residue incorporation associated with tillage. This can delay planting and possibly decrease the number of days available for timely planting. Effective tile drainage is necessary for many Ontario soils to ensure a reasonable opportunity for timely no-till corn planting. Good drainage also helps to provide a favourable seedbed environment for rapid, deep root growth. Producers on fine-textured soils often discover that successful no-till is very difficult in fields that are not systematically tile drained. These fine-textured fields with inadequate tile drainage will often require some type of fall tillage to maximize yield potential.

Crop Rotation

In Ontario, no-till corn generally produces similar yields to tilled systems when following crops that produce low residues, such as soybeans, dry edible beans or forages harvested as hay or haylage. For soils with relatively slow internal drainage, increasing the amount of surface residue cover can slow soil drying, and delay the opportunity for timely planting and conditions that promote fast, deep, early-season root growth. Improved soil structure and higher earthworm activity associated with soils following forages may contribute to the success of no-till corn production following forages. No-till corn grown on medium- and fine-textured soils that follow crops producing high residue often struggle to achieve optimum yields, regardless of careful management for other parts of the production system. If the choice is made to maintain residue cover following high residue crops such as grain corn or cereals, some tillage will likely be required. This will increase the chance of timely planting and maximum yield potential.

Residue Management

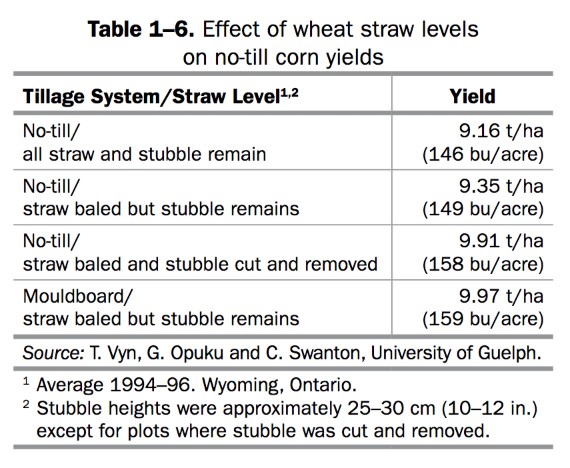

Reducing tillage costs, improving net profits and enhancing long-term soil health requires decisions about how best to handle crop residues, particularly wheat straw. Where no-till or reduced till corn is to follow wheat, remove the wheat straw from the field. Table 1–6, Effect of wheat straw levels on no-till corn yields, summarizes corn yields from tillage trials where three different levels of straw were left on the field and corn was no-till planted the following year. Removing straw from fields, especially in high-yielding wheat crops and on heavier-textured soils, increased the potential for no-till corn yields to equal those of mouldboard plowing.

Where straw removal is not an option, uniform spreading of the straw and chaff is critical for no-till or reduced tillage success in corn. Even where straw is to be left in the windrow, it is important to spread the chaff as widely and evenly as possible during combining. In cool, wet springs, the lower soil temperatures, poorer growth and potential slug damage brought on by mats of decaying wheat residue often result in yield losses that may have been avoided by uniform spreading of residue.

The benefits of incorporating all of the straw might outweigh the advantages of reducing tillage. For farms where erosion potential is higher, adopting a reduced tillage system is likely more sustainable, even with the need to remove some straw. Another option is using a system where wheat fields receive a small amount of tillage to partially incorporate straw while still leaving the soil surface largely protected. Researchers examined the impact of adding nitrogen to assist in straw breakdown. Results indicate that straw did not decay more quickly where nitrogen was spread on wheat straw in the fall. In addition, the soil nitrogen levels the following spring were not higher compared to where no nitrogen was applied.

Weed Control

For corn yield potential to be realized, optimum weed control is required. Additional management in no-till cropping systems may be needed to control perennial weeds and weed species that are new to the system due to a shift in weed populations. Spring pre-plant burndown treatments are critical in allowing the crop to develop without weed interference during critical early growth phases.

Disease and Insect Management

Tillage can play a role in preventing or suppressing certain pest and disease issues. Weeds, volunteer plants from the previous crop and certain cover crops left on the soil surface through the winter and early spring can increase the risk of some insect pests. Low lying weeds such as chickweed are ideal for egg laying by black cutworm moths that fly in from the southern United States (U.S.) in early spring. Cereal aphids can transmit vector viruses from volunteer wheat plants and infect the newly planted cereal crop. Corn planted into a rye cover crop increases the risk of armyworm infestations. Achieving good weed and cover crop management through herbicide applications in the fall and tillage in early spring at least 3 weeks prior to planting can avoid some of these pest risks. Tillage can be used in attempt to reduce populations of wireworms and grubs by bringing them up to the soil surface, exposing them to their natural enemies. However, caution is warranted as several passes are required and may not provide adequate control. Tillage can actually increase the risk of one particular pest, seedcorn maggot, if weeds, manure or cover crops are incorporated into the soil shortly before planting. Incorporation needs to occur at least 3 weeks prior to planting to ensure that the adults are no longer attracted to the decaying vegetation.

Some diseases are more prone to no-till systems as tillage can help in disease management. Tillage helps the soil to warm up and dry quickly, reducing the risk of seedling diseases. Some stalk rot diseases can also be managed through tillage though in some cases, crop rotation and hybrid selection play a larger role in disease management.

More details on insect pests and diseases of corn can be found in Chapter 15 and Chapter 16.

Fertilizer Placement

Nutrient stratification (nutrients concentrated near the soil surface) may occur in long-term, no-till fields. Without the option to incorporate or mix dry fertilizer material in the no-till system, fertilizer placement becomes increasingly important. Studies done in Ontario and the U.S. cornbelt have shown that applying phosphorus and potassium in starter fertilizer bands resulted in yield response in no-till systems to be similar to fall mouldboard systems. This is especially evident in cases when soil tests indicated low to medium soil fertility levels of K. Planter-banded phosphorus and potassium were utilized more efficiently compared to fall surface broadcast in no-till systems. However, on sites with low fertility, a combination of broadcast and planter banding may be necessary to maximize no-till yields. Cooler- and less-aerated soils in no-till systems often have a slower rate of nitrogen mineralization compared to conventional tillage systems. This is often overcome by applying 35 kg/ha (30 lb/acre) of nitrogen in the starter fertilizer.

| Applying 35 kg/ha (30 lb/acre) of nitrogen in the starter on no-till corn planters has often overcome the slower nitrogen mineralization frequently present in no-till soils, where the balance of the nitrogen is applied in a side-dress application. |

Soil Compaction

The best option for preventing soil compaction is to avoid field operations when soils are wet. Soil compaction is often cited as one of the reasons no-till corn may yield less than conventionally tilled corn. An option for enhancing corn yields in reduced tillage systems may include incorporating deep rooted crops into the rotation, and/or extensive loosening of soil deeper into the soil profile. This can be done without disrupting much of the crop residue on the soil surface and can be confined to zones where next year’s corn rows will be planted (e.g., strip-tillage).

Usually the most effective method to minimize the risk of deep compaction, 35–45 cm (15–18 in.) depth is to reduce the number of field operations and/or minimize use of equipment with heavy axles (e.g., grain buggies) wherever possible. Avoiding field traffic when soils are wet will also help minimize compaction.

Tire management can help reduce soil compaction in the root zone (top 20 cm (8 in.)). Increasing floatation by minimizing inflation pressures can reduce the impacts of tires, especially in the surface soil layers. This requires three key steps:

1. Know the axle load that each tire is carrying.

2. Know the manufacturers specifications for that tire.

3. Adjust inflation pressures down to the minimum acceptable pressure for soil conditions (speed, load type, duals, etc.). A good target for tire inflation pressures to reduce soil compaction is 1 Bar (14.5 PSI).

Planter Performance

Optimal planter performance is necessary to maximize corn yield potential in any tillage system. Planter performance and/or suitability are especially critical in no-till systems. Absence of tillage results in greater variability in near-surface soil properties and residue cover, therefore ensuring that planting equipment is properly maintained and adjusted for no-till planting conditions will lessen variability in corn plant stand and emergence, and increase yields in no-till systems.

This is an excerpt of the no-till and other considerations section from the corn chapter of Ontario Ministry of Agriculture, Food and Rural Affair’s “Agronomy Guide for Field Crops – Publication 811”. The whole corn chapter can be viewed as PDF here. All chapters are online, and can be viewed by searching the internet for “Agronomy Guide for Field Crops – Publication 811”. Special thanks to Andrew Priest, OMAFRA summer student, for producing these Field Crop News excerpts.