Summary

- It is important to be aware of soil compaction on or around corn rows during planting

- Trials completed in Niagara region and Oxford County during spring/summer 2021 comparing the yield differences between trafficked rows (planting corn into planter tractor tire tracks), rows bordered by row crop tires and untrafficked rows, found no statistical significance across all locations

- In Oxford County, there was a significant yield reduction (6 bu/ac) for rows between two row crop relative to rows not near tire traffic.

This article was written by Gia Shelp, OMAFRA Corn Specialist Assistant, Summer 2022.

As the assistant to OMAFRA corn specialist Ben Rosser this summer, I have had first-hand experience on the importance of avoiding compaction in fields. From being mindful of how I drive machinery in our research plots to visiting farmer’s fields and seeing the potential impacts of driving on corn rows in relation to corn yields.

Background

Concerns and questions of soil compaction during corn planting have been brought to light. Growers are wondering if driving on or beside corn rows affects corn yield. Considering compaction is an inevitable cause for concern in all fields, it is important to understand the potential impacts and alternatives to the issue. Starting last year, data has been collected on the yield differences during crop planting of trafficked rows (planting corn into planter tractor tire tracks), planting near row crop tires and rows not near any tire traffic from the Niagara and the Oxford County regions.

Trial Information

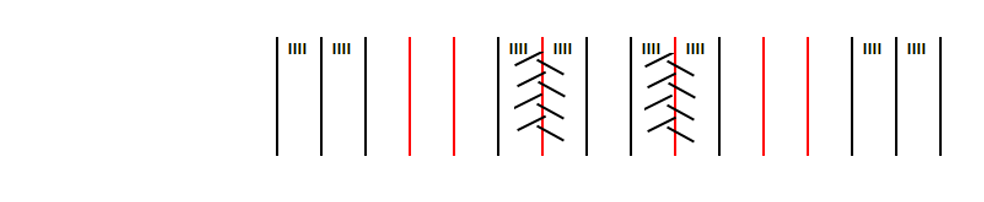

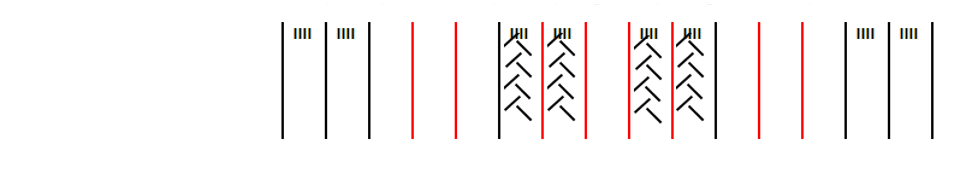

Two case studies from 2021 provide examples of differences in trafficked and non-trafficked rows. The trial followed pairs of neighbouring farmers from both regions – one who planted corn into trafficked rows, and one who planted using row crop tires. Trafficked rows refers to farmers who plant corn into planter tractor tires tracks (Figure 1). Row crop tires refers to tires that drive between the rows of corn to be planted (Figure 2). All growers used row-hopper planters so weight from central fill seed tanks would not confound results.

In these regions during the spring/summer of 2021 the environment was dry/fit throughout corn planting season, therefore additional environmental factors (wet or poor planting conditions) may not have significantly affected the data. All rows were hand harvested at the end of the season. For additional information, the Niagara region farmer trafficking rows used front 600/70R30 tires at 10 psi and rear 710-70R42 tires at 16 psi. The Oxford County farmer trafficking rows used a rubber tracked tractor. Neighbouring farmers not trafficking rows were using row crop dual tires

Results

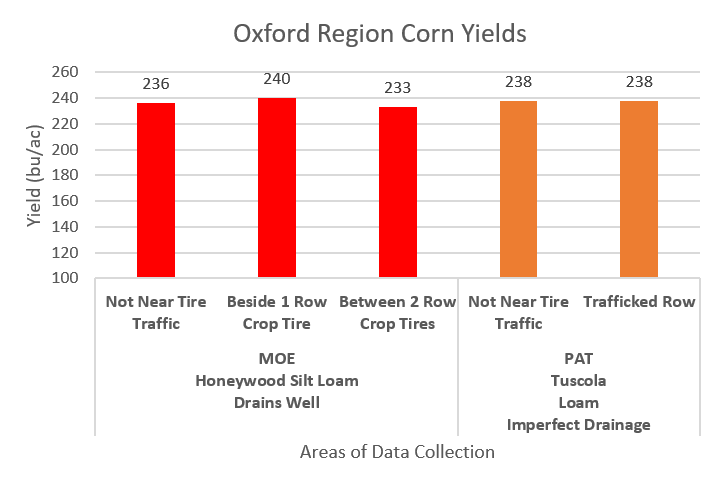

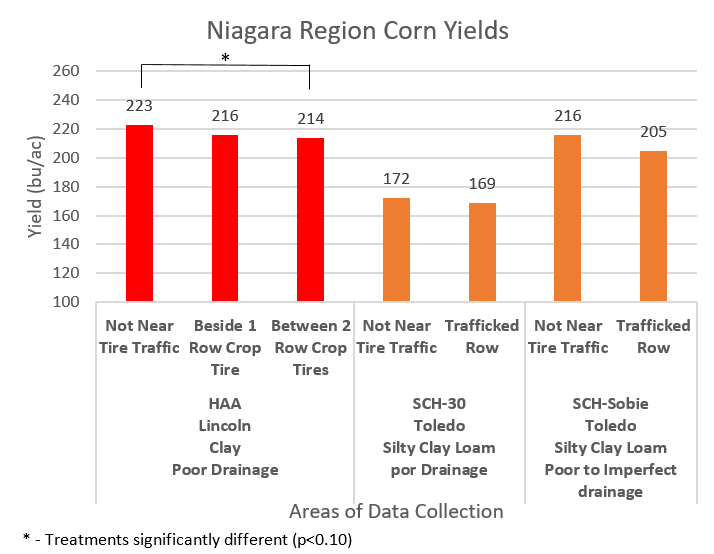

As presented in the graphs (see Figure 3 and 4) there are differences between the treatment groups.

Across all fields, there were no significant yield impact of trafficked rows compared to rows not near tire traffic. While average yields were different, there was enough background variability that the two rows yielded corn which were statistically similar.

Averaging both row-crop locations (data not shown) there was a 6 bu/ac reduction (significant p<0.10) for rows between two crop tires relative to rows not near tire traffic, but no significant difference between other treatments. In the Niagara Region there was no significant yield effect between either row crop tire rows and rows not near tire traffic.

In the Oxford region, there was significant differences between rows not near crop tires and rows between crop tires. This information is significant in the sense that even with tires that do not intercept with the rows, there may still be impact on crop yields. Even farmers with row crop tires then may have yield loss in nearby rows while planting. Important to note, that because trials were held in separate fields, the yield comparisons of treatments should only be made within each field.

One might expect any yield losses to occur from some combination of tire trafficking in the corn row, and/or from tractor weight applied in or around the corn rows. At a limited number of trials in 2021, it was interesting to note that there was more consistent yield impact at trials where corn rows were bordered by two narrow row crop tires than where corn rows were trafficked with wide tires or tracks

As growers you want to find greater yield in your crop while still being efficient on time and money. Therefore, this information is important for aiding farmers in making educated decisions on tire and placement types in relation to corn yields. These findings in this article are based on the spring/summer of 2021 data collection. The trial is ongoing.