Simple Summary

- there is limited guidance for safe fertilizer rates for strip till – unlike 2”x2” planter banding, there are many different fertilizer placement options in strip till

- there is likely some tradeoff with fertilizer placement in strip till – placement closer to the seed likely improves starter fertilizer effect and fertilizer efficiency, but likely also increases risks

- a new project is trying to develop some safe-rate guidelines for common strip till fertilizer placements

What Are Safe Fertilizer Rates?

What are safe rates of fertilizer for strip till? This is one of the most common strip till question I get.

Beyond talking to strip tillers about their personal experiences, there is limited safe-rate guidance. Maximizing rates may improve logistical efficiencies, maximize yield responses to fertilizer, and possibly reduce needs for other in-crop applications or broadcast applications made in other crops. At some point though, crop safety becomes a concern.

Ontario does have safe fertilizer rates for in-furrow and 2”x2” planter banding (Table 1), but unlike these placements, strip till fertilizer placement can vary significantly across, and even within various strip tiller types. For instance, some coulter strip tillers are mixing fertilizer throughout the strips, while some shank-style strip tillers may be banding fertilizer behind the shank – some maybe 6” deep, others shallower, maybe 4”, to try to get some starter fertilizer effect.

Table 1. Maximum safe rates of nutrients in fertilizer for in-furrow and 2”x2” planter banding for corn in 30” rows (Brown, 2017).

| Placement | Fertilizer | Nitrogen | Nitrogen + Potash + Sulphur |

| 2”x2” Band | Blend Containing Urea | 36 lb-N/ac | 104 lb-N+K+S/ac |

| 2”x2” Band | Blend Not Containing Urea | 46 lb-N/ac | 104 lb-N+K+S/ac |

| In-Furrow | Blend Containing Urea | Not Recommended | Not Recommended |

| In-Furrow | Blend Not Containing Urea | 9 lb-N/ac | 18 lb-N+K+S/ac |

There is some tradeoff with fertilizer placement in the strip:

- the closer to the seed, the more we might benefit from starter fertilizer effect (fertilizer readily accessible by corn seedlings at very early growth stages), but the sooner we may see crop injury if we increase rates.

- Increased separation between seed and fertilizer gains crop safety but may reduce starter fertilizer effect.

New Research Project

To build data to assist in safe-rate decisions, a new project has started at the University of Guelph with soil fertility and nutrient management professor John Lauzon through Grain Farmers of Ontario and Canadian Agricultural Partnership funding.

Fertilizer Placement

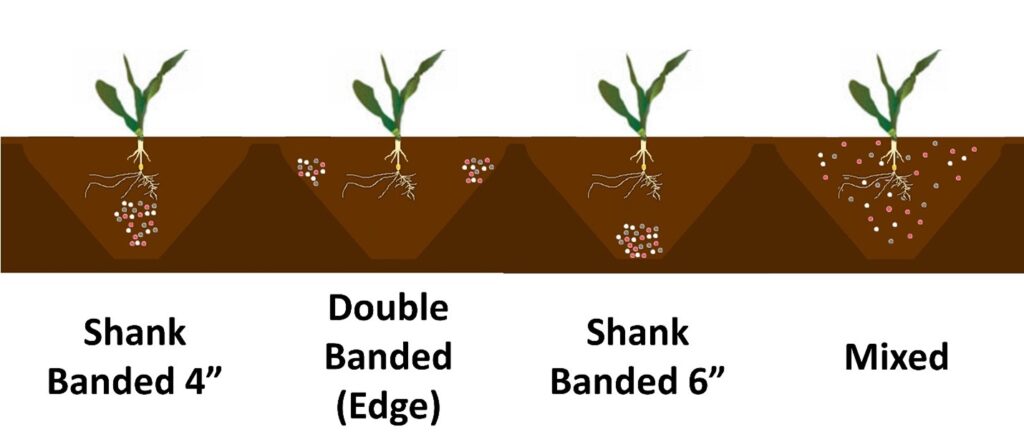

A custom-built 4-row strip tiller (Fig. 1) is used to investigate 4 strip placements that may reflect more common fertilizer placements used by strip tillers (Fig. 2):

- Fertilizer released at 4” depth behind shank – reflecting where fertilizer is released shallower to hopefully provide some starter fertilizer effect, but possibly at a higher risk for fertilizer injury.

- Fertilizer banded at the edges of the strips – while not common among commercial units, some Ontario growers have custom built strip tillers to deliver fertilizer on the strip edges with the idea of keeping fertilizer out of the seed zone (for safety) while hopefully having it in a place that can still provide starter fertilizer effect.

- Fertilizer released at 6” depth behind shank – reflecting where fertilizer is placed deeper to avoid safety risks, but possibly at the expense of starter fertilizer effect.

- Fertilizer mixed throughout strip – reflecting where fertilizer may be mixed throughout the strip with either a shank or coulter strip till unit, avoiding concentrations of fertilizer.

Figure 1. Custom built 4-row strip tiller with 4 different fertilizer placements.

Figure 2. Four strip till fertilizer placements investigated with custom strip tiller.

Fertilizer Blends

Of course, safe rates for various placements will depend on the fertilizer being used. To cover fertilizer scenarios that might be more common among strip tillers, the project will look at safe rates of:

- Fall potash – are there any residual risks to higher fall potash rates, particularly in very low testing fields where a grower would like to build and apply higher rates through a fall application?

- Spring urea – where a grower would like to only apply N in the spring strip, maybe representing a scenario where P and K was applied in the fall or met other ways such as manure.

- Spring balanced NPK blend (urea + MAP + potash, e.g. 19-19-19) – to represent scenarios where growers will apply P and K in the spring strip, but also want to include a reasonable amount of N in the same pass.

- Spring balanced PK blend (MAP + potash, e.g. 5-27-27) – to represent scenarios where growers will apply P and K in the spring strip, but most N is applied outside the strip, such as a top-dress or sidedress application.

Because soil texture will impact crop safety, trials are conducted on clay-loam, loam and sand-type soils. Populations, emergence timing and emergence and crop stage variability are recorded as measures of fertilizer injury.

Beyond just safe rates, these treatments may also shed light on which of these fertilizer placements are more efficient for yield response to fertilizer. At locations with low soil tests, there were visual differences across row units during mid vegetative stages.

Overall, there likely isn’t one perfect placement in the strip. Optimum placement likely depends on the goal of the system (starter response, crop safety), and is likely a function of any single producer’s existing soil tests, needs for starter fertilizer effect in the strip till pass, desired fertilizer rates and logistics.

References

Brown, C (editor). 2017. Agronomy Guide for Field Crops Publication 811. Queen’s Printer for Ontario.