This article is based on work performed by Mike Schryver, BASF Technical Service Specialist. It was originally published at Sprayers101.com, and you may have been redirected here from that site.

Introduction

Nitrogen is an essential nutrient required throughout a plant’s lifecycle. It is commonly applied to corn in either a granular form as urea or in a liquid form as urea-ammonium nitrate (UAN). Depending on soil type and precipitation, significant amounts of nitrogen can be lost to leaching, denitrification and volatilization as N2O (a greenhouse gas). Learn more about nitrogen in soil in this excellent overview by University of Minnesota Extension.

With the 2020 announcement of Canada’s Strengthened Climate Plan, Ontario is committed to a 30% reduction of 2020 N2O emission levels by 2030. Adding urease and nitrification inhibitors (aka stabilizers) to nitrogen fertilizer applications is an environmentally sustainable practice that reduces nitrogen losses and improves yield.

Another essential plant nutrient, Sulphur, is applied in liquid-form as ammonium thiosulphate (ATS). Primarily used to increase corn yields, high rates (approx. >10% by volume) of ATS can also inhibit urease and nitrification, albeit not as well as other nitrogen stabilizing options.

In the pursuit of productivity, UAN and ATS are often combined to serve as an herbicide carrier in corn weed-and-feed applications. However, liquid fertilizers are dense solutions that contain charged ions and exhibit a reduced capacity for solubilizing pesticides. This complicates the tank mixing process. When micronutrients like sulfur are added to nitrogen-based formulations, physical incompatibilities can arise that cause uneven applications and can even clog sprayers.

Given the known compatibility issues, questions have been raised about the best way to introduce urease and nitrification inhibitors to tank mixes of UAN, ATS and herbicide. Specifically:

- Stabilizer Compatibility: What is the impact of adding nitrogen stabilizers to UAN carriers containing leading corn herbicides formulated as emulsifiable concentrates (EC) or suspension concentrates (SC)?

- Mixing Order: When UAN and ATS are premixed, does their ratio, or the addition of nitrogen stabilizer affect tank mix compatibility with herbicides?

To answer these questions, we performed a series of jar tests.

Method

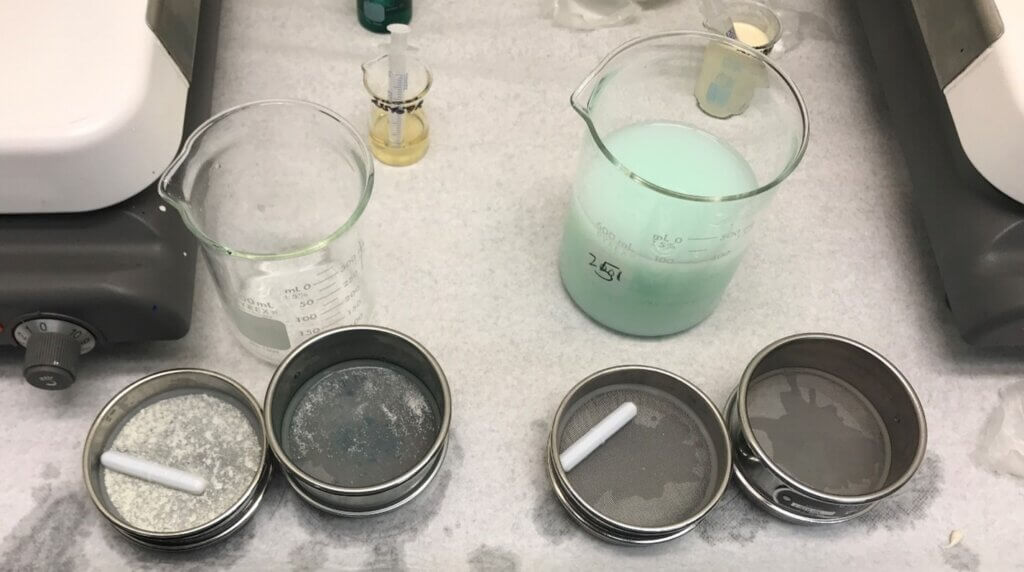

300 ml jars with magnetic stir bars were mixed to reflect a 10 gpa application. UAN was chilled to approx. -5°C and herbicides were added at 2x the labelled rate to simulate a worse-case scenario. Nitrogen stabilizer was added at a ratio per manufacturer’s instructions. Products were introduced at 1 minute intervals to provide sufficient time for solubilization. Jars were left to rest for at least 1 hour after mixing, and then agitated to simulate interrupted spray jobs. The solution was then poured through a 100 mesh screen to simulate a worst case scenario for sprayers that typical employ 50 mesh filters.

| Herbicides | Fertilizer carriers | Stabilizers |

| Leading EC Herbicide | UAN: 28% | eNtrench NXTGEN (Corteva) |

| Leading SC Herbicide | ATS: 12-0-0-26% SU | Anvol (Koch) |

| Tribune (Koch) | ||

| Agrotain (Koch) | ||

| Neon Surface (NexusBioAg) | ||

| SylLock plus (Sylvite) | ||

| Excelis Maxx (Timac) |

Results

Stabilizer Compatibility

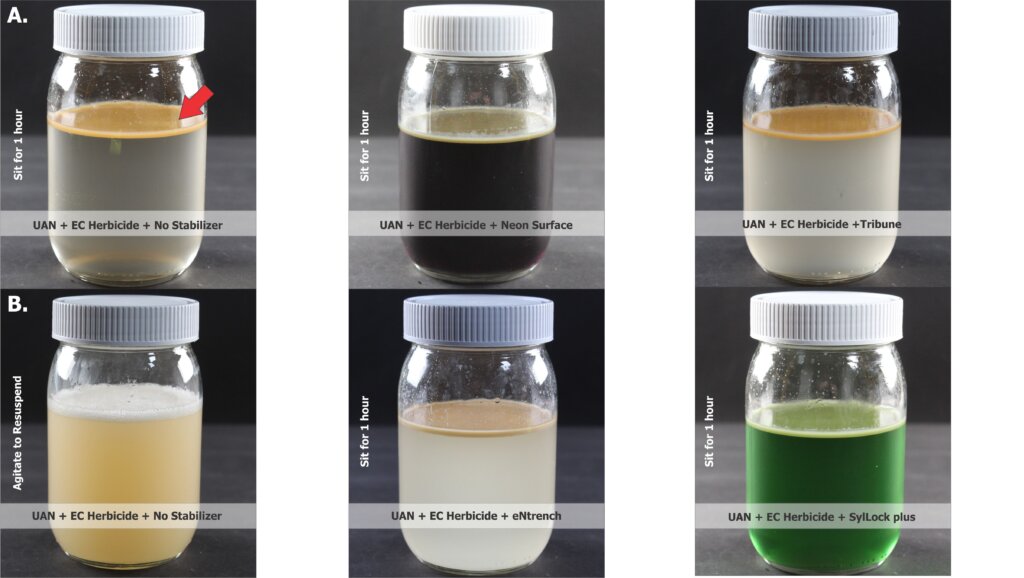

EC herbicides have active ingredients that are soluble in water and include immiscible solvents. When added at 2x label rate to chilled UAN, followed by a stabilizer, agitation created an acceptable suspension (Figure 1). The EC separated to the top of the mixture following an hour rest but was easily reintegrated. There was no appreciable residue left behind when poured through a 100 mesh screen.

SC herbicides have active ingredients that are water insoluble, but stable in an aqueous environment. When added at 2x label rate to chilled UAN, followed by a stabilizer, agitation created an acceptable suspension (Figure 2). The SC flocculated and formed a sediment at the bottom of the mixture following an hour rest but was easily reintegrated. There was no appreciable residue left behind when poured through a 100 mesh screen.

Best Practices

- Contact manufacturers and conduct a jar test to confirm compatibility

- Ensure thorough agitation (with or without a stabilizer, and especially after tank has settled)

- Components may separate to the top (ECs) or settle on the bottom (SCs)

Mixing Order

Mixing order was tested using chilled UAN, ATS, and EC herbicide. It is well known that ATS should be added last in the tank mix order, and mixes that include a higher load of ATS relative to UAN exacerbate tank mix issues.

This is seen in the following video where we combine 203 ml of chilled UAN, 30 ml of SC corn herbicide and 68 ml of ATS. On the left, UAN, then herbicide, then ATS mixes perfectly. However, when we start with UAN, then add ATS (which represents premixed fertilizer) then the herbicide does not suspend, and prolonged agitation does not improve the situation. The video is shown at 2x speed.

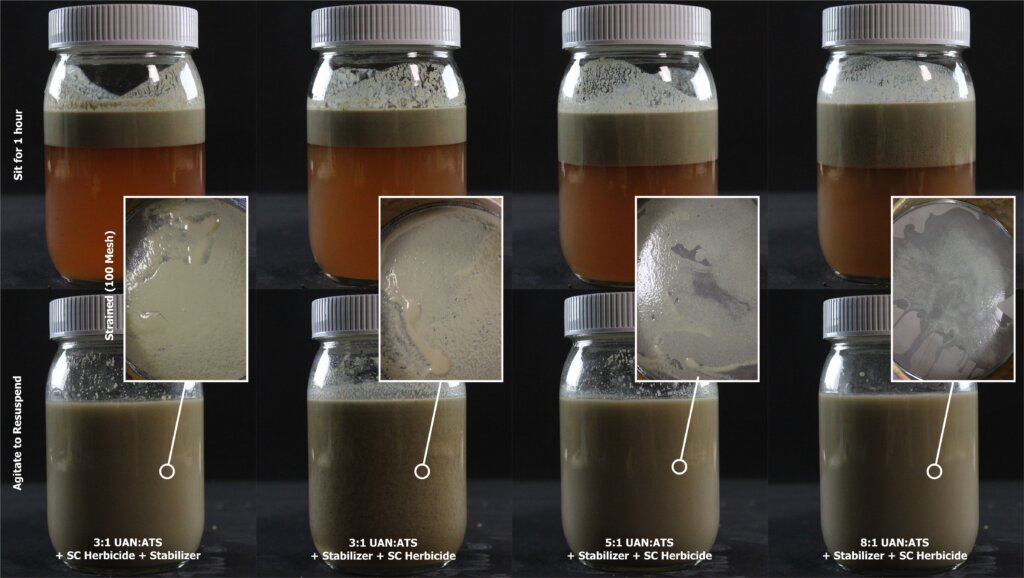

We then added a nitrogen stabilizer to the series to see if it could correct the tank mix issue arising from adding ATS immediately after UAN. This replicates the situation an operator would face when purchasing UAN and ATS premixed. We also reduced the ratio of UAN to ATS from 3:1, to 5:1 to 8:1 to establish a threshold ratio that alleviated tank mix issues (Figure 3). All solutions were poured through 100 mesh screens to capture residue (Figure 4).

Best Practices

- Contact manufacturers and conduct a jar test to confirm compatibility

- ATS must be added after the herbicide (EC or SC). The stabilizer can be added last, but preferably ATS is the last ingredient in the tank.

- Adding stabilizer will not reverse a tank mix error arising from adding ATS prior to the herbicide.

- The higher the concentration of ATS, the higher the risk of incompatibility. A 5:1 ratio of UAN to ATS failed while a ratio of 8:1 succeeded. The threshold is likely 7:1.